Product Description

Click Here Get More Information

Our Advantages

Equipment

3-axis, 4-axis and full 5-axis processing equipment, CNC lathe, centering machine, turning and milling compound, wire cutting, EDM, grinding, etc

Processing

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

Materials

Aluminum, metal, steel, metal, plastic, metal, brass, bronze, rubber, ceramic, cast iron, glass, copper, titanium, metal, titanium, steel, carbon fiber, etc

Tolerance

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

Quality Assurance

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

Tolerance

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment |

Machining Workshop

Production Process

Quality Guarantee

Click Here Get Free Quotation

Application industry

CNC Machining Parts Can Be Used in Many Industry

Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries, Instruments & Meters, Office equipments, Home appliance, Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc

Areospace

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons, Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears,Differential Housing, Axle Shafts

Auto&Motorcycle

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons,Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears, Differential Housing, Axle Shafts

Energy

Drill Pipes and Casing, Impellers Casings, Pipe Control Valves, Shafts, Wellhead Equipment, Mud Pumps, Frac Pumps, Frac Tools,Rotor Shafts and disc

Robotics

Custom robotic end-effectors, Low-volume prototype, Pilot, Enclosures, Custom tooling, Fixturing

Medical Industry

Rotary Bearing Seal Rings for CHINAMFG Knife,CT Scanner Frames,Mounting Brackets,Card Retainers for CT Scanners,Cooling Plenums for CT Scanners,Brackets for CT Scanners,Gearbox Components,Actuators,Large Shafts

Home Appliances

Screws, hinges, handles, slides, turntables, pneumatic rods, guide rails, steel drawers

Certifications

FAQ

Q1. What kind of production service do you provide?

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Simple Assembly and Various Metal Surface Treatment.

Q2. How about the lead time?

Mould : 3-5 weeks

Mass production : 3-4 weeks

Q3. How about your quality?

♦Our management and production executed strictly according to ISO9001 : 2008 quality System.

♦We will make the operation instruction once the sample is approval.

♦ We will 100% inspect the products before shipment.

♦If there is quality problem, we will supply the replacement by our shipping cost.

Q4. How long should we take for a quotation?

After receiving detail information we will quote within 24 hours

Q5. What is your quotation element?

Drawing or Sample, Material, finish and Quantity.

Q6. What is your payment term?

Mould : 50% prepaid, 50% after the mould finish, balance after sample approval.

Goods : 50% prepaid, balance T/T before shipment.

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory, Aerospace/ Marine/Automotive/Medical Equipments |

|---|---|

| Standard: | GB, EN, China GB Code |

| Surface Treatment: | Anodizing,Polishing,Brushing, Plating, Oxide Black |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining, Turning, Milling, Forging |

| Material: | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Customized |

| Samples: |

US$ 0.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in automotive applications?

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

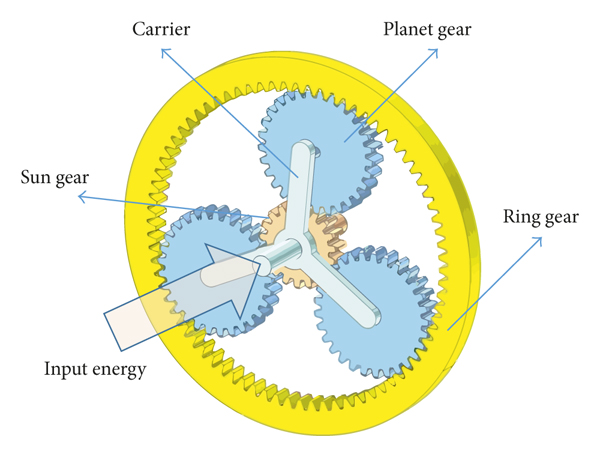

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

What is the role of a sun gear in the operation of a differential gear system?

The sun gear plays a vital role in the operation of a differential gear system, which is commonly used in vehicles to distribute power between the wheels while allowing them to rotate at different speeds. The sun gear, along with other gears in the differential, contributes to the smooth and efficient operation of the system. Here’s an explanation of the role of a sun gear in the operation of a differential gear system:

- Power Input:

The sun gear serves as the input for the differential gear system. It receives torque from the driveshaft or propeller shaft, which transfers power from the engine or transmission to the differential. The rotation of the sun gear initiates the power flow within the differential assembly.

- Speed Differentiation:

The primary function of the differential gear system is to allow the wheels to rotate at different speeds while distributing power between them. The sun gear, along with the other gears in the differential, enables this speed differentiation.

As the sun gear rotates, it meshes with the planet gears, which are arranged around it. The planet gears, in turn, engage with the ring gear, which is connected to the axle shafts leading to the wheels. The interaction between the sun gear, planet gears, and ring gear allows the differential to accommodate different rotational speeds of the wheels.

- Distribution of Torque:

Another critical role of the sun gear is to distribute torque between the wheels in a differential system. The torque input from the sun gear is transmitted to the planet gears, which then transfer the torque to the ring gear and, subsequently, to the axle shafts and wheels.

As the differential operates, it adjusts the distribution of torque based on the traction and resistance encountered by each wheel. If one wheel experiences less resistance or has more traction than the other, the differential will allocate more torque to that wheel. This torque distribution helps optimize power delivery, improve traction, and enhance vehicle stability during cornering or uneven road conditions.

- Equal Torque Split (Open Differential):

In an open differential system, which is the most common type, the sun gear plays a role in equal torque split between the wheels under normal driving conditions. When both wheels have equal traction and resistance, the sun gear distributes torque equally to the planet gears, resulting in an equal torque split between the wheels.

However, in situations where one wheel loses traction or encounters less resistance, such as during wheel slip or when one wheel is on a slippery surface, the open differential will prioritize torque delivery to the wheel with less traction, potentially reducing overall traction and performance.

- Limited-Slip Differential:

In some differential systems, such as limited-slip differentials (LSDs), the sun gear’s role is modified to provide improved traction and torque distribution. LSDs use various mechanisms, such as clutch packs or viscous fluids, to limit the speed differentiation between the wheels and redirect torque to the wheel with more traction.

In LSDs, the sun gear’s engagement with the other gears is modified to allow for controlled torque transfer, enhancing traction and stability during challenging driving conditions.

In summary, the sun gear in a differential gear system serves as the power input and enables speed differentiation and torque distribution between the wheels. Its role is crucial for ensuring smooth power delivery, optimizing traction, and enhancing vehicle stability in various driving conditions.

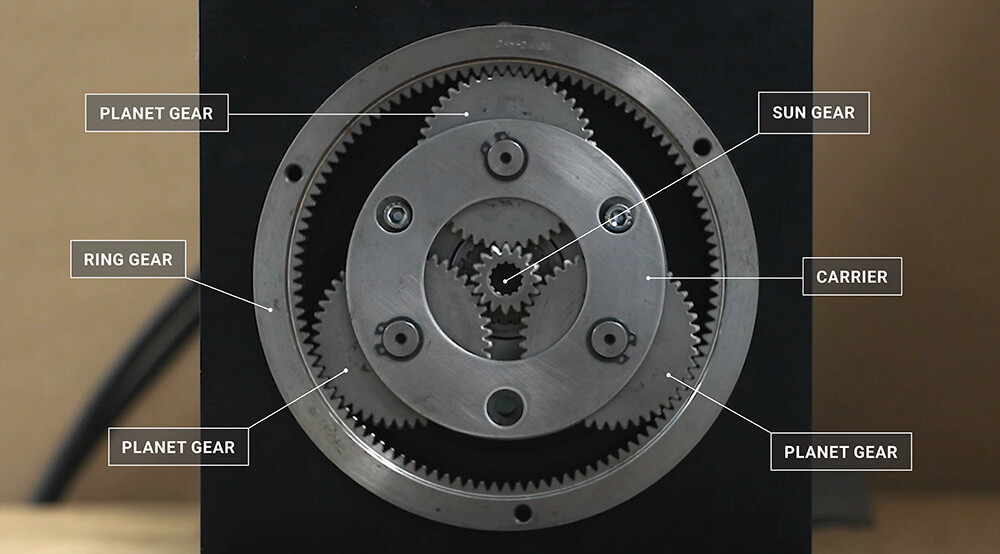

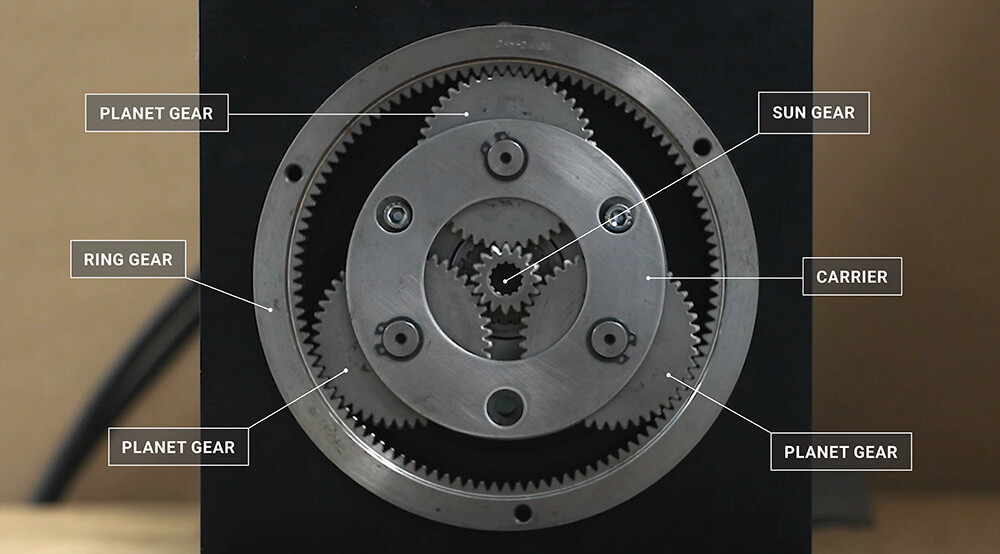

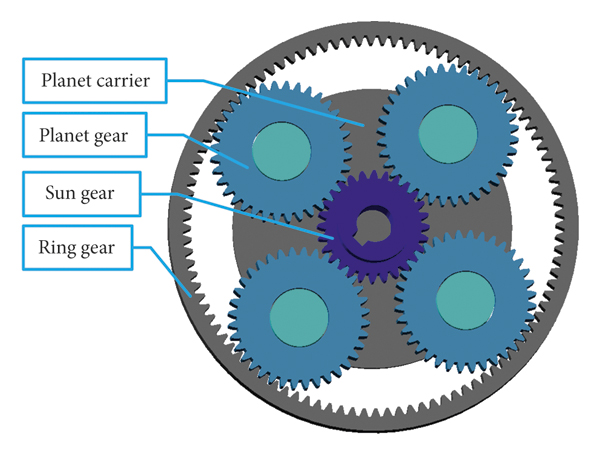

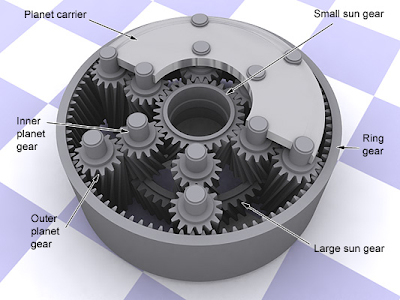

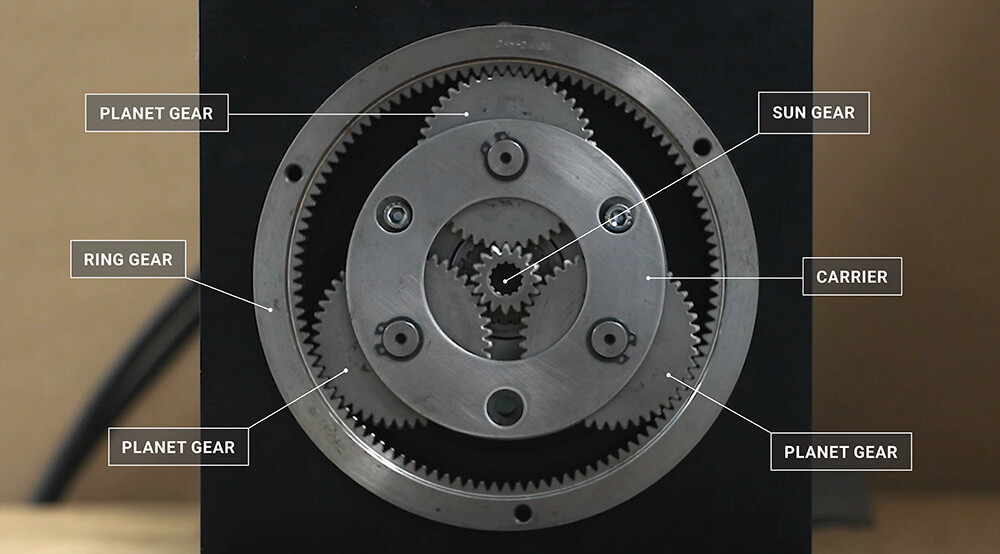

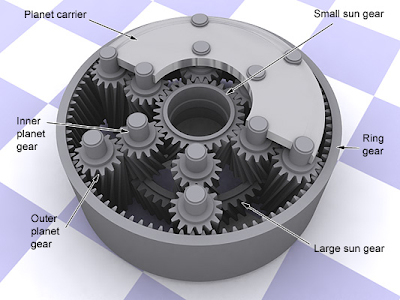

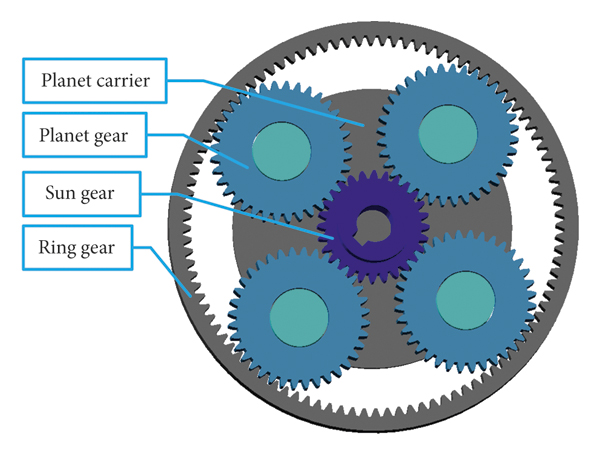

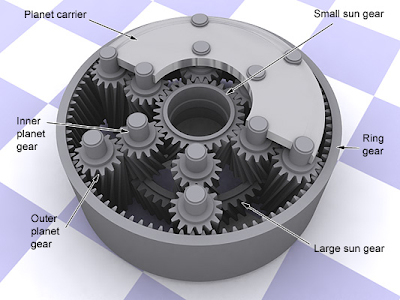

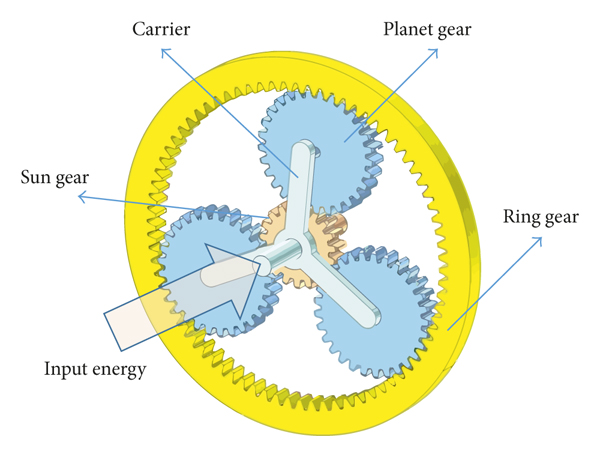

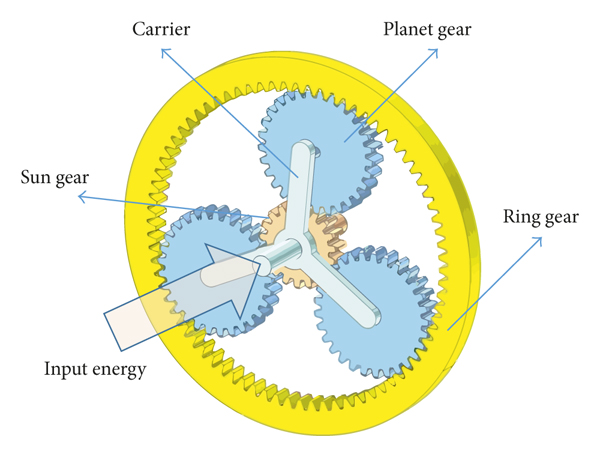

Can you explain the role of a sun gear in planetary gear systems?

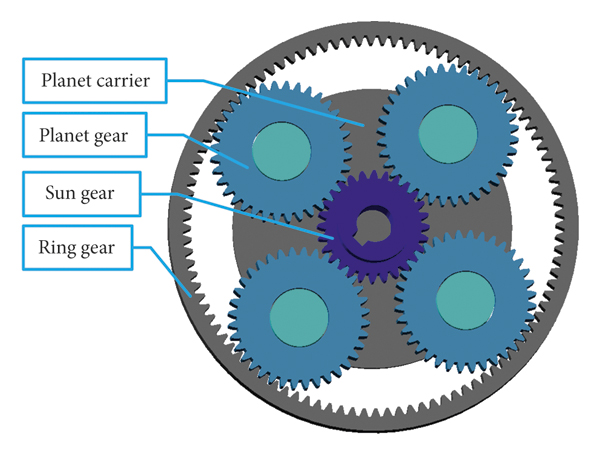

The sun gear plays a crucial role in planetary gear systems, contributing to their unique functionality and versatility. Understanding the specific role of the sun gear within these systems helps in comprehending their overall operation. Here’s an explanation of the role of a sun gear in planetary gear systems:

- Power Input: The sun gear serves as the primary power input element in a planetary gear system. It receives rotational motion and torque from an external source, such as an engine or motor. This power input is transmitted to other gears within the system.

- Engagement with Planet Gears: One of the distinctive features of a planetary gear system is the interaction between the sun gear and multiple planet gears. The planet gears are smaller gears that surround the sun gear and mesh with both the sun gear and an outer ring gear. This engagement allows for the transfer of torque and motion between the gears.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. This power distribution mechanism enables the sharing of torque among multiple gears within the system, allowing for load distribution and efficient power transmission.

- Gear Ratio Control: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, planetary gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This flexibility in gear ratio control enables planetary gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Torque Amplification: A key advantage of planetary gear systems is their ability to amplify torque. By employing a combination of the sun gear, planet gears, and ring gear, torque can be multiplied or reduced depending on the gear ratio configuration. This torque amplification feature is beneficial in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Another notable aspect of planetary gear systems is their directional control capability. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to gear systems, enabling them to be used in various mechanical applications.

In summary, the sun gear in planetary gear systems serves as the power input element, engages with planet gears, distributes torque, controls gear ratios, provides torque amplification, and enables directional control. Its role is essential in achieving efficient power transmission, versatile gear ratios, and adaptable functionality in a wide range of mechanical applications.

editor by CX 2023-10-11

China Professional Spur Drive Transmission Sun Planetary Ring Gears gear ratio calculator

Product Description

Product Description

Product Parameters

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Type: | Circular Gear |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a sun gear contribute to the overall efficiency of a gear arrangement?

A sun gear plays a significant role in determining the overall efficiency of a gear arrangement. Let’s explore how a sun gear contributes to the efficiency of a gear system:

- Power Transmission:

The sun gear serves as the primary driver in many gear systems, transmitting power from the input source to the output component. Its contribution to power transmission efficiency is crucial. A well-designed sun gear ensures minimal power loss during the transfer of rotational force.

Efficiency is influenced by factors such as gear material, surface finish, and lubrication. The sun gear’s design, including its tooth profile, size, and alignment with other gears, affects the smoothness of power transmission, minimizing energy losses due to friction and misalignment.

- Load Distribution:

The interaction between the sun gear and other gears, such as planet gears or ring gears, influences load distribution within the gear arrangement. An efficient sun gear design ensures that the load is evenly distributed across all engaged gears, reducing the stress on individual gear teeth.

Uniform load distribution helps prevent premature wear and damage to the gears, enhancing overall efficiency and extending the gear system’s lifespan. By efficiently distributing the load, the sun gear contributes to a more balanced distribution of forces within the gear arrangement.

- Reduced Friction and Wear:

The sun gear’s smooth operation is vital for minimizing friction and wear within the gear system. When the sun gear meshes with other gears, such as planet gears or ring gears, it should have proper tooth engagement and alignment.

An accurately designed sun gear reduces sliding friction and ensures a rolling contact between the gear teeth. This rolling contact reduces wear, heat generation, and energy losses due to friction. By minimizing friction and wear, the sun gear enhances the overall efficiency of the gear arrangement.

- Optimized Gear Ratios:

The sun gear’s size and its relationship to other gears in the arrangement significantly impact the gear ratios. Efficient gear ratios are essential for achieving the desired output speed and torque in a gear system.

An optimized sun gear design, along with carefully selected sizes for other gears, allows for efficient gear ratio selection. This ensures that the gear system operates within the desired speed and torque range, maximizing the overall efficiency of the arrangement.

- Minimized Energy Losses:

An efficient sun gear design aims to minimize energy losses within the gear arrangement. Energy losses can occur due to factors such as friction, misalignment, and inefficient power transmission.

By focusing on factors like gear tooth profile, material selection, lubrication, and proper alignment, the sun gear can contribute to the reduction of energy losses. Minimizing energy losses improves the overall efficiency of the gear arrangement, ensuring more effective utilization of input power.

- System Optimization:

The sun gear’s contribution to the overall efficiency of a gear arrangement is part of a broader system optimization process. Engineers consider various factors, including gear design, material selection, lubrication, and operating conditions, to maximize the efficiency of the entire gear system.

The sun gear, as a vital component, is optimized in conjunction with other gears and system parameters to achieve the desired efficiency levels. Its design and performance directly impact the overall efficiency of the gear arrangement.

In conclusion, the sun gear’s contribution to the overall efficiency of a gear arrangement lies in its role in power transmission, load distribution, friction reduction, optimized gear ratios, and minimizing energy losses. By considering these factors and optimizing the sun gear’s design, engineers can enhance the efficiency and performance of gear systems in various applications.

What are the considerations for lubrication and maintenance of sun gears?

Proper lubrication and maintenance of sun gears are crucial for ensuring their optimal performance, longevity, and reliability. Sun gears, like other mechanical components, require appropriate lubrication to minimize friction, reduce wear, and prevent damage. Here are some considerations for lubrication and maintenance of sun gears:

- Lubrication:

Effective lubrication is essential for sun gears to operate smoothly and efficiently. Consider the following aspects:

- Lubricant Selection: Choose a lubricant that is specifically designed for gear applications. The lubricant should have the necessary viscosity, additives, and thermal stability to provide adequate lubrication and protection to the sun gears under the operating conditions.

- Proper Lubricant Application: Ensure that the lubricant is applied correctly to the sun gears. This can involve methods such as oil baths, oil mist systems, or grease application, depending on the specific gear system and its requirements. Follow the manufacturer’s guidelines or consult with lubrication experts for the appropriate lubrication technique.

- Regular Lubricant Inspection: Monitor the lubricant condition regularly to ensure its effectiveness and to detect any signs of contamination, degradation, or insufficient lubrication. Perform oil analysis or visual inspections as recommended by lubrication experts or equipment manufacturers.

- Maintenance:

Proper maintenance practices help keep sun gears in optimal working condition and extend their service life. Consider the following maintenance considerations:

- Regular Inspections: Conduct routine inspections of the sun gears to check for any signs of wear, damage, misalignment, or abnormal operating conditions. Inspections can help identify potential issues early, allowing for timely maintenance or repairs.

- Torque and Load Monitoring: Keep track of the torque and load applied to the sun gears. Ensure that the gear system is not subjected to excessive loads or overloading, as this can lead to premature wear and failure. Use appropriate monitoring techniques, such as load sensors or torque meters, to ensure the gear system operates within its designed limits.

- Alignment and Gear Meshing: Ensure proper alignment and gear meshing between the sun gear, planet gears, and ring gear. Misalignment or improper gear engagement can cause excessive wear and damage to the gear system. Regularly check and adjust the gear alignment as needed.

- Proactive Repairs and Replacements: If any issues, such as worn teeth, damaged gear components, or abnormal vibrations, are detected during inspections or monitoring, take proactive measures to repair or replace the affected parts. Timely repairs can prevent further damage and improve the overall performance and reliability of the sun gears.

- Operating Conditions: Consider the operating conditions of the gear system, such as temperature, humidity, and environmental factors. Ensure that the sun gears are protected from excessive heat, moisture, contaminants, and corrosive substances that can adversely affect their performance and durability.

In summary, proper lubrication and maintenance of sun gears are critical for their optimal performance and longevity. Considerations include selecting the right lubricant, applying it correctly, inspecting the lubricant regularly, conducting routine inspections, monitoring torque and load, ensuring proper alignment and gear meshing, performing proactive repairs and replacements, and considering the operating conditions. Adhering to these considerations helps ensure reliable and efficient operation of sun gears in various mechanical systems.

What are the advantages of using a sun gear in a planetary gear set?

The utilization of a sun gear in a planetary gear set offers several advantages, contributing to the popularity and wide range of applications of this gear configuration. Understanding the specific benefits of using a sun gear helps in appreciating its advantages in mechanical systems. Here’s an explanation of the advantages of using a sun gear in a planetary gear set:

- Torque Amplification: One of the significant advantages of a planetary gear set with a sun gear is its ability to amplify torque. By arranging the sun gear, planet gears, and an outer ring gear, torque can be multiplied or reduced depending on the specific gear ratio configuration. This torque amplification feature is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Compact Design: Planetary gear sets with a sun gear often enable a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions, where a smaller and lighter gear system is desirable.

- High Gear Ratios: The presence of a sun gear in a planetary gear set facilitates the attainment of high gear ratios. By manipulating the sizes and arrangements of the sun gear, planet gears, and ring gear, a wide range of gear ratios can be achieved. This flexibility in gear ratio control enables planetary gear sets to provide various output speeds and torque levels, allowing for customization based on the specific requirements of the mechanical system.

- Load Distribution: The sun gear’s engagement with multiple planet gears in a planetary gear set allows for load distribution among the gears. This distributed load-sharing characteristic helps in reducing the load on individual gears, resulting in improved reliability and longevity of the gear system. It also enables efficient power distribution and helps prevent excessive wear and stress on any single gear within the system.

- Directional Control: Planetary gear sets with a sun gear provide versatile directional control. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control feature adds flexibility to mechanical systems, allowing for a wide range of applications that require bidirectional power transmission.

- Multiple Output Shafts: Another advantage of using a sun gear in a planetary gear set is the possibility of having multiple output shafts. By incorporating additional planet gears and output shafts, a planetary gear set with a sun gear can deliver power to multiple outputs simultaneously. This feature is beneficial in applications that require power distribution to multiple subsystems or components within a complex mechanical system.

In summary, the advantages of using a sun gear in a planetary gear set include torque amplification, compact design, high gear ratios, load distribution, directional control, and the potential for multiple output shafts. These advantages make planetary gear sets with a sun gear well-suited for a wide range of applications, including automotive, aerospace, machinery, robotics, and more.

editor by CX 2023-10-08

China Hot selling 1st Stage Sun Gear of Wind Power Planetary Gearbox gear cycle

Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Products

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft’s production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CHINAMFG has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CHINAMFG products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Wind Turbine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Customization: |

Available

| Customized Request |

|---|

How does a sun gear contribute to the overall efficiency of a gear arrangement?

A sun gear plays a significant role in determining the overall efficiency of a gear arrangement. Let’s explore how a sun gear contributes to the efficiency of a gear system:

- Power Transmission:

The sun gear serves as the primary driver in many gear systems, transmitting power from the input source to the output component. Its contribution to power transmission efficiency is crucial. A well-designed sun gear ensures minimal power loss during the transfer of rotational force.

Efficiency is influenced by factors such as gear material, surface finish, and lubrication. The sun gear’s design, including its tooth profile, size, and alignment with other gears, affects the smoothness of power transmission, minimizing energy losses due to friction and misalignment.

- Load Distribution:

The interaction between the sun gear and other gears, such as planet gears or ring gears, influences load distribution within the gear arrangement. An efficient sun gear design ensures that the load is evenly distributed across all engaged gears, reducing the stress on individual gear teeth.

Uniform load distribution helps prevent premature wear and damage to the gears, enhancing overall efficiency and extending the gear system’s lifespan. By efficiently distributing the load, the sun gear contributes to a more balanced distribution of forces within the gear arrangement.

- Reduced Friction and Wear:

The sun gear’s smooth operation is vital for minimizing friction and wear within the gear system. When the sun gear meshes with other gears, such as planet gears or ring gears, it should have proper tooth engagement and alignment.

An accurately designed sun gear reduces sliding friction and ensures a rolling contact between the gear teeth. This rolling contact reduces wear, heat generation, and energy losses due to friction. By minimizing friction and wear, the sun gear enhances the overall efficiency of the gear arrangement.

- Optimized Gear Ratios:

The sun gear’s size and its relationship to other gears in the arrangement significantly impact the gear ratios. Efficient gear ratios are essential for achieving the desired output speed and torque in a gear system.

An optimized sun gear design, along with carefully selected sizes for other gears, allows for efficient gear ratio selection. This ensures that the gear system operates within the desired speed and torque range, maximizing the overall efficiency of the arrangement.

- Minimized Energy Losses:

An efficient sun gear design aims to minimize energy losses within the gear arrangement. Energy losses can occur due to factors such as friction, misalignment, and inefficient power transmission.

By focusing on factors like gear tooth profile, material selection, lubrication, and proper alignment, the sun gear can contribute to the reduction of energy losses. Minimizing energy losses improves the overall efficiency of the gear arrangement, ensuring more effective utilization of input power.

- System Optimization:

The sun gear’s contribution to the overall efficiency of a gear arrangement is part of a broader system optimization process. Engineers consider various factors, including gear design, material selection, lubrication, and operating conditions, to maximize the efficiency of the entire gear system.

The sun gear, as a vital component, is optimized in conjunction with other gears and system parameters to achieve the desired efficiency levels. Its design and performance directly impact the overall efficiency of the gear arrangement.

In conclusion, the sun gear’s contribution to the overall efficiency of a gear arrangement lies in its role in power transmission, load distribution, friction reduction, optimized gear ratios, and minimizing energy losses. By considering these factors and optimizing the sun gear’s design, engineers can enhance the efficiency and performance of gear systems in various applications.

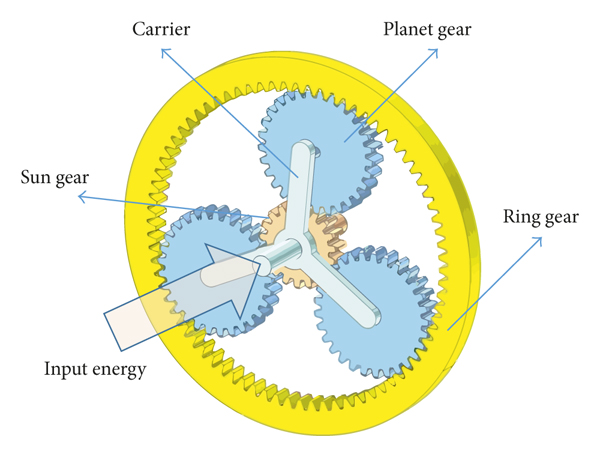

Can you explain the function of a sun gear in automatic transmissions?

The sun gear plays a crucial role in the operation of automatic transmissions. It is an essential component within the planetary gear set, which is responsible for transmitting power and controlling gear ratios in automatic transmissions. Here’s an explanation of the function of a sun gear in automatic transmissions:

- Power Input:

The sun gear serves as one of the primary power input sources in an automatic transmission. It connects to the torque converter, which is a fluid coupling that transfers engine power to the transmission. The rotation of the sun gear receives torque from the engine and acts as the initial input for the gear set.

- Gear Ratio Control:

The sun gear, along with other gears in the planetary gear set, allows for the control of gear ratios in an automatic transmission. By varying the engagement and rotation of the sun gear, different gear ratios can be achieved, providing the desired combination of torque multiplication and speed reduction or increase.

The gear ratio control is achieved through the interaction between the sun gear, planet gears, and ring gear. The sun gear is connected to the planet gears, which in turn mesh with the ring gear. The arrangement and rotation of these gears determine the gear ratio and, consequently, the output speed and torque of the transmission.

- Forward and Reverse Operation:

The sun gear’s function also extends to enabling both forward and reverse operation in automatic transmissions. By controlling the engagement of the sun gear with other gears in the planetary set, the transmission can switch between forward and reverse directions.

In the forward operation, the sun gear engages with the planet gears and the ring gear, transmitting power from the input shaft to the output shaft with a specific gear ratio. In the reverse operation, the sun gear engages with a different set of gears, causing the rotation of the output shaft to reverse its direction.

- Torque Multiplication:

Another important function of the sun gear is torque multiplication. By utilizing the planetary gear set arrangement, the sun gear can multiply or reduce torque depending on the gear ratio configuration. This torque multiplication capability allows the transmission to provide higher torque output when needed, such as during acceleration or climbing steep gradients.

- Gear Shifts:

The sun gear’s function also contributes to smooth and efficient gear shifts in automatic transmissions. As gear shifts occur, the transmission control unit adjusts the engagement of the sun gear, planet gears, and ring gear to achieve the desired gear ratio for the target speed and load conditions.

During gear shifts, the engagement of clutches or bands controlled by the transmission control unit ensures that the sun gear rotates with the desired set of gears, allowing for seamless transitions between different gear ratios. This coordinated operation of the sun gear and other gears facilitates smooth acceleration and deceleration without excessively straining the transmission components.

In summary, the sun gear in automatic transmissions serves multiple functions, including power input from the torque converter, gear ratio control through its engagement with other gears, enabling forward and reverse operation, torque multiplication for increased output, and contributing to smooth gear shifts. These functions collectively allow automatic transmissions to provide efficient power transfer, dynamic gear ratios, and smooth operation in various driving conditions.

How does a sun gear differ from other types of gears?

A sun gear has distinct characteristics that set it apart from other types of gears. While gears serve various purposes in mechanical systems, understanding the specific features of a sun gear can help differentiate it from other gear types. Here’s an explanation of how a sun gear differs from other gears:

- Central Position: Unlike many other gears that are located on the periphery of a gear system, a sun gear is positioned at the center of a planetary gear arrangement. It serves as a central driver within the system, transmitting torque to other gears.

- Engagement with Planet Gears: A defining feature of a sun gear is its engagement with multiple planet gears. These planet gears surround the sun gear and mesh with both the sun gear and an outer ring gear. The interaction between the sun gear and the planet gears allows for the transfer of torque and power distribution within the gear system.

- Gear System Configuration: Sun gears are commonly found in planetary gear systems, where they function as a central component. Planetary gear systems consist of a sun gear, planet gears, and an outer ring gear. The arrangement and interaction of these gears enable various gear ratios, torque multiplication, and directional control.

- Power Input: In a planetary gear system, the sun gear typically receives power input from an external source, such as an engine or motor. It serves as the primary driving element that initiates torque transmission and power distribution within the system.

- Role in Gear Ratio: The sun gear’s size, number of teeth, and its interaction with the planet gears and ring gear determine the overall gear ratio. By altering the sizes and arrangements of these gears, manufacturers can achieve different speed and torque combinations, providing versatility in gear system applications.

While a sun gear has its unique characteristics, it is essential to note that gears come in various types and configurations, each serving specific purposes in mechanical systems. Different types of gears include spur gears, helical gears, bevel gears, worm gears, and more. Each type has its own design, tooth profile, and applications, catering to different needs such as speed reduction, torque multiplication, directional control, or noise reduction.

In summary, a sun gear differentiates itself through its central positioning, engagement with planet gears, configuration in planetary gear systems, role as a power input element, and influence on gear ratio. Understanding these distinctions helps in recognizing the specific functions and applications of sun gears within mechanical systems.

editor by CX 2023-10-07

China Professional Diesel Engine Truck Sun Gear 2405035ck96 CZPTCZPTCZPT manufacturer

Product Description

| 1 | Long standing reputation in this field |

| 2 | Specialization is standard and accurate meet your requirement |

| 3 | OEM quality standard guaranteed |

| 4 | Product upgrading and expansion of species |

| 5 | Good quality with competitive prices. |

| 6 | Flexible and convenient logistic service. |

| 7 | Excellent and high-quality control |

| 8 | Long lasting working life time. |

| 9 | Sufficient storage |

Product Description

| Product Name | diesel engine truck Sun gear 2405035CK96 CHINAMFG CHINAMFG CHINAMFG CHINAMFG AUMAN |

| Material | Plastic + Metal |

| Function | adjusting |

| Package | Factory package |

Specifications

1.This diesel engine truck Sun gear 2405035CK96 CHINAMFG CHINAMFG CHINAMFG CHINAMFG AUMAN

2. Both genuine and oem are available, high quality ones also are in stock

3.The size is standard and the shape is Round

4.And we also can supply the whole parts for HW19712 gearbox assembly

FAQ

Q1: Can you also supply Heavy Truck parts?

A1: Yes, We specialize in Sinotruk, Shacman, such as HOWO, CHINAMFG F3000,F2000, etc.

Q2: What’s the MOQ?

A2: Usually MOQ is according to different products,5 -10PCS/model for stock items.

Q3: What’s the delivery time?

A3: It takes 5-7 days if there is stock, and takes 1 month if there is no stock.

Q4: What’s the payment term?

A4: All by T/T, 30% in advance, 70% balance before shipping; option: L/C at sight.

Q5: What’s the packaging?

A5: Neutral packing or customer make packing

Our Services

– OEM Manufacturing is welcome: Product, Package…

– Customized design exclusive sealing products

– Specially designed for SINOTRUK, CHINAMFG series

– Installation guide

– Product maintenance training

– Free sample for your test

– We will reply your inquiry in 24 hours

| Application: | HOWO |

|---|---|

| Function: | HOWO |

| Layout: | Omit |

| Hardness: | Omit |

| Installation: | Omit |

| Step: | Omit |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

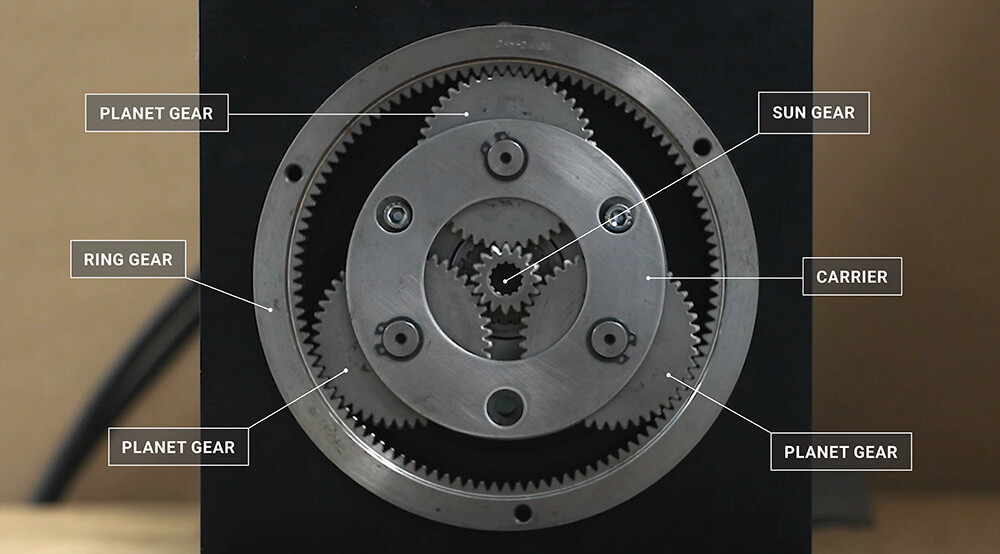

Can you describe the interaction between sun gears and planet gears?

The interaction between sun gears and planet gears is a fundamental aspect of gear systems. Let’s delve into the details of this interaction:

- Planetary Gear Systems:

The interaction between sun gears and planet gears primarily occurs in planetary gear systems. These systems consist of multiple planet gears that rotate around a central sun gear while meshing with an outer ring gear. This arrangement allows for various mechanical advantages and functionalities.

- Power Transmission:

The sun gear serves as the primary driver in a planetary gear system. When power is applied to the sun gear, it transmits rotational force to the planet gears. The planet gears, due to their meshing with both the sun gear and the ring gear, distribute the transmitted power evenly across all the gears.

As the sun gear rotates, the planet gears rotate in the opposite direction around the sun gear while also rotating around their own axes. This rotational movement of the planet gears, driven by the sun gear, plays a crucial role in power transmission within the gear system.

- Speed and Torque Ratios:

The interaction between the sun gear and planet gears affects the speed and torque ratios in a gear system. By choosing different sizes for the sun gear and planet gears, engineers can manipulate the gear ratios to achieve specific outcomes.

When the sun gear is larger than the planet gears, it results in a higher speed ratio. In this case, the sun gear rotates faster than the planet gears, leading to an output shaft or ring gear with increased rotational speed relative to the input shaft or sun gear.

Conversely, when the sun gear is smaller than the planet gears, it leads to a lower speed ratio. In this scenario, the sun gear rotates slower than the planet gears, resulting in an output shaft or ring gear with reduced rotational speed compared to the input shaft or sun gear.

Similarly, the interaction between the sun gear and planet gears affects the torque ratio. When the sun gear is larger than the planet gears, it amplifies the torque, resulting in higher output torque relative to the input torque. Conversely, when the sun gear is smaller, it reduces the torque, resulting in lower output torque compared to the input torque.

- Direction Reversal:

The interaction between the sun gear and planet gears also enables torque direction reversal in planetary gear systems. When the sun gear rotates in a specific direction, it imparts torque to the planet gears, causing them to rotate in the opposite direction around the sun gear.

This counterclockwise rotation of the planet gears, as driven by the sun gear, leads to the ring gear rotating in the opposite direction. By reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Mechanical Advantages:

The interaction between sun gears and planet gears offers several mechanical advantages. The distribution of torque across multiple planet gears allows for increased load-bearing capacity and improved system reliability. As each planet gear shares the load, the overall stress on individual gears is reduced, enhancing the system’s durability.

Moreover, the arrangement of sun gears and planet gears in a planetary gear system results in compact designs and high power density. The distributed power transmission and torque-sharing characteristics enable the system to handle higher loads while occupying minimal space.

In summary, the interaction between sun gears and planet gears in planetary gear systems is crucial for power transmission, achieving speed and torque ratios, enabling torque direction reversal, and providing mechanical advantages such as load distribution and compact designs. Understanding this interaction is essential for designing and optimizing gear systems in various applications.

What are the considerations for lubrication and maintenance of sun gears?

Proper lubrication and maintenance of sun gears are crucial for ensuring their optimal performance, longevity, and reliability. Sun gears, like other mechanical components, require appropriate lubrication to minimize friction, reduce wear, and prevent damage. Here are some considerations for lubrication and maintenance of sun gears:

- Lubrication:

Effective lubrication is essential for sun gears to operate smoothly and efficiently. Consider the following aspects:

- Lubricant Selection: Choose a lubricant that is specifically designed for gear applications. The lubricant should have the necessary viscosity, additives, and thermal stability to provide adequate lubrication and protection to the sun gears under the operating conditions.

- Proper Lubricant Application: Ensure that the lubricant is applied correctly to the sun gears. This can involve methods such as oil baths, oil mist systems, or grease application, depending on the specific gear system and its requirements. Follow the manufacturer’s guidelines or consult with lubrication experts for the appropriate lubrication technique.

- Regular Lubricant Inspection: Monitor the lubricant condition regularly to ensure its effectiveness and to detect any signs of contamination, degradation, or insufficient lubrication. Perform oil analysis or visual inspections as recommended by lubrication experts or equipment manufacturers.

- Maintenance:

Proper maintenance practices help keep sun gears in optimal working condition and extend their service life. Consider the following maintenance considerations:

- Regular Inspections: Conduct routine inspections of the sun gears to check for any signs of wear, damage, misalignment, or abnormal operating conditions. Inspections can help identify potential issues early, allowing for timely maintenance or repairs.

- Torque and Load Monitoring: Keep track of the torque and load applied to the sun gears. Ensure that the gear system is not subjected to excessive loads or overloading, as this can lead to premature wear and failure. Use appropriate monitoring techniques, such as load sensors or torque meters, to ensure the gear system operates within its designed limits.

- Alignment and Gear Meshing: Ensure proper alignment and gear meshing between the sun gear, planet gears, and ring gear. Misalignment or improper gear engagement can cause excessive wear and damage to the gear system. Regularly check and adjust the gear alignment as needed.

- Proactive Repairs and Replacements: If any issues, such as worn teeth, damaged gear components, or abnormal vibrations, are detected during inspections or monitoring, take proactive measures to repair or replace the affected parts. Timely repairs can prevent further damage and improve the overall performance and reliability of the sun gears.

- Operating Conditions: Consider the operating conditions of the gear system, such as temperature, humidity, and environmental factors. Ensure that the sun gears are protected from excessive heat, moisture, contaminants, and corrosive substances that can adversely affect their performance and durability.

In summary, proper lubrication and maintenance of sun gears are critical for their optimal performance and longevity. Considerations include selecting the right lubricant, applying it correctly, inspecting the lubricant regularly, conducting routine inspections, monitoring torque and load, ensuring proper alignment and gear meshing, performing proactive repairs and replacements, and considering the operating conditions. Adhering to these considerations helps ensure reliable and efficient operation of sun gears in various mechanical systems.

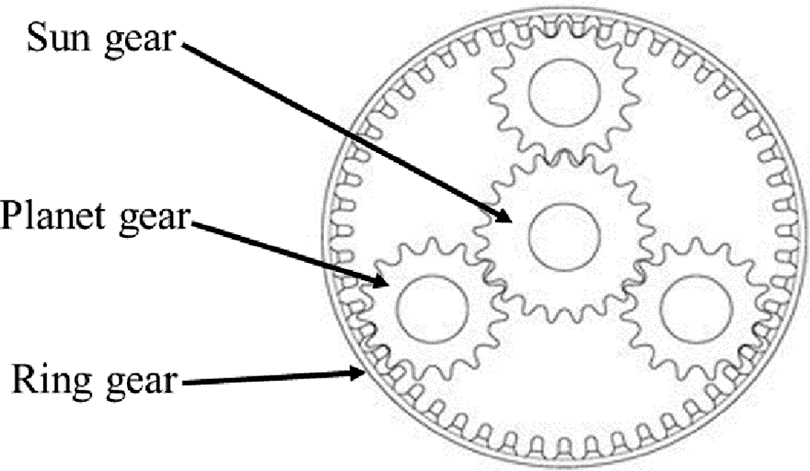

Can you explain the role of a sun gear in planetary gear systems?

The sun gear plays a crucial role in planetary gear systems, contributing to their unique functionality and versatility. Understanding the specific role of the sun gear within these systems helps in comprehending their overall operation. Here’s an explanation of the role of a sun gear in planetary gear systems:

- Power Input: The sun gear serves as the primary power input element in a planetary gear system. It receives rotational motion and torque from an external source, such as an engine or motor. This power input is transmitted to other gears within the system.

- Engagement with Planet Gears: One of the distinctive features of a planetary gear system is the interaction between the sun gear and multiple planet gears. The planet gears are smaller gears that surround the sun gear and mesh with both the sun gear and an outer ring gear. This engagement allows for the transfer of torque and motion between the gears.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. This power distribution mechanism enables the sharing of torque among multiple gears within the system, allowing for load distribution and efficient power transmission.

- Gear Ratio Control: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, planetary gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This flexibility in gear ratio control enables planetary gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Torque Amplification: A key advantage of planetary gear systems is their ability to amplify torque. By employing a combination of the sun gear, planet gears, and ring gear, torque can be multiplied or reduced depending on the gear ratio configuration. This torque amplification feature is beneficial in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Another notable aspect of planetary gear systems is their directional control capability. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to gear systems, enabling them to be used in various mechanical applications.

In summary, the sun gear in planetary gear systems serves as the power input element, engages with planet gears, distributes torque, controls gear ratios, provides torque amplification, and enables directional control. Its role is essential in achieving efficient power transmission, versatile gear ratios, and adaptable functionality in a wide range of mechanical applications.

editor by CX 2023-09-28

China wholesaler Diesel Engine Truck Sun Gear 2405035ck96 CZPTCZPTCZPT helical bevel gear

Product Description

| 1 | Long standing reputation in this field |

| 2 | Specialization is standard and accurate meet your requirement |

| 3 | OEM quality standard guaranteed |

| 4 | Product upgrading and expansion of species |

| 5 | Good quality with competitive prices. |

| 6 | Flexible and convenient logistic service. |

| 7 | Excellent and high-quality control |

| 8 | Long lasting working life time. |

| 9 | Sufficient storage |

Product Description

| Product Name | diesel engine truck Sun gear 2405035CK96 CHINAMFG CHINAMFG CHINAMFG CHINAMFG AUMAN |

| Material | Plastic + Metal |

| Function | adjusting |

| Package | Factory package |

Specifications

1.This diesel engine truck Sun gear 2405035CK96 CHINAMFG CHINAMFG CHINAMFG CHINAMFG AUMAN

2. Both genuine and oem are available, high quality ones also are in stock

3.The size is standard and the shape is Round

4.And we also can supply the whole parts for HW19712 gearbox assembly

FAQ

Q1: Can you also supply Heavy Truck parts?

A1: Yes, We specialize in Sinotruk, Shacman, such as HOWO, CHINAMFG F3000,F2000, etc.

Q2: What’s the MOQ?

A2: Usually MOQ is according to different products,5 -10PCS/model for stock items.

Q3: What’s the delivery time?

A3: It takes 5-7 days if there is stock, and takes 1 month if there is no stock.

Q4: What’s the payment term?

A4: All by T/T, 30% in advance, 70% balance before shipping; option: L/C at sight.

Q5: What’s the packaging?

A5: Neutral packing or customer make packing

Our Services

– OEM Manufacturing is welcome: Product, Package…

– Customized design exclusive sealing products

– Specially designed for SINOTRUK, CHINAMFG series

– Installation guide

– Product maintenance training

– Free sample for your test

– We will reply your inquiry in 24 hours

| Application: | HOWO |

|---|---|

| Function: | HOWO |

| Layout: | Omit |

| Hardness: | Omit |

| Installation: | Omit |

| Step: | Omit |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does the size of a sun gear affect the gear ratio in planetary systems?

The size of the sun gear plays a significant role in determining the gear ratio in planetary gear systems. The gear ratio determines the relationship between the input speed and torque and the output speed and torque in the system. Here’s an explanation of how the size of the sun gear affects the gear ratio in planetary systems:

- Direct Proportion:

In a planetary gear system, the gear ratio is influenced by the relative sizes of the sun gear, planet gears, and ring gear. The gear ratio is typically expressed as the ratio of the output speed to the input speed or the ratio of the output torque to the input torque.

When considering the size of the sun gear, it is important to understand that the gear ratio is inversely proportional to the size of the sun gear. In other words, as the size of the sun gear increases, the gear ratio decreases, and vice versa.

- Power Distribution:

The size of the sun gear affects the power distribution within the planetary system. As the sun gear rotates, it engages with the planet gears, which, in turn, mesh with the ring gear. The interaction between these gears determines the gear ratio.

A larger sun gear allows for a higher number of teeth on the sun gear itself as well as on the planet gears. This means that each rotation of the sun gear will result in a smaller rotation of the planet gears and the ring gear. Consequently, a larger sun gear leads to a lower gear ratio, reducing the output speed and increasing the output torque.

- Torque Amplification:

Another factor influenced by the size of the sun gear is torque amplification. In planetary gear systems, the sun gear’s size affects the torque multiplication or reduction capabilities of the system.

With a larger sun gear, the system can provide higher torque output for a given input torque, resulting in torque amplification. This can be advantageous in applications where increased torque is required, such as during vehicle acceleration or heavy load conditions.

Conversely, a smaller sun gear reduces the torque output of the system, resulting in torque reduction. This can be useful in situations where a lower torque output is desired, such as when precise control is required or when operating in low-torque applications.

- Overall Gear Ratio Range:

The size of the sun gear also affects the overall gear ratio range that can be achieved in a planetary system. By varying the size of the sun gear relative to the other gears, different gear ratios can be achieved, allowing for a wider range of output speeds and torques.

For example, if a system requires a higher gear ratio range, a larger sun gear can be used in combination with appropriately sized planet gears and a ring gear. Conversely, if a lower gear ratio range is desired, a smaller sun gear can be employed.

It’s important to note that the size of the sun gear alone does not determine the gear ratio. The gear ratio is influenced by the combination of the sizes of all the gears within the planetary system.

In summary, the size of the sun gear in a planetary gear system has a direct impact on the gear ratio, power distribution, torque amplification, and overall gear ratio range. A larger sun gear results in a lower gear ratio, while a smaller sun gear leads to a higher gear ratio. The size of the sun gear, along with the sizes of the other gears, determines the performance characteristics of the planetary system.

What are the considerations for lubrication and maintenance of sun gears?

Proper lubrication and maintenance of sun gears are crucial for ensuring their optimal performance, longevity, and reliability. Sun gears, like other mechanical components, require appropriate lubrication to minimize friction, reduce wear, and prevent damage. Here are some considerations for lubrication and maintenance of sun gears:

- Lubrication:

Effective lubrication is essential for sun gears to operate smoothly and efficiently. Consider the following aspects:

- Lubricant Selection: Choose a lubricant that is specifically designed for gear applications. The lubricant should have the necessary viscosity, additives, and thermal stability to provide adequate lubrication and protection to the sun gears under the operating conditions.

- Proper Lubricant Application: Ensure that the lubricant is applied correctly to the sun gears. This can involve methods such as oil baths, oil mist systems, or grease application, depending on the specific gear system and its requirements. Follow the manufacturer’s guidelines or consult with lubrication experts for the appropriate lubrication technique.

- Regular Lubricant Inspection: Monitor the lubricant condition regularly to ensure its effectiveness and to detect any signs of contamination, degradation, or insufficient lubrication. Perform oil analysis or visual inspections as recommended by lubrication experts or equipment manufacturers.

- Maintenance:

Proper maintenance practices help keep sun gears in optimal working condition and extend their service life. Consider the following maintenance considerations:

- Regular Inspections: Conduct routine inspections of the sun gears to check for any signs of wear, damage, misalignment, or abnormal operating conditions. Inspections can help identify potential issues early, allowing for timely maintenance or repairs.

- Torque and Load Monitoring: Keep track of the torque and load applied to the sun gears. Ensure that the gear system is not subjected to excessive loads or overloading, as this can lead to premature wear and failure. Use appropriate monitoring techniques, such as load sensors or torque meters, to ensure the gear system operates within its designed limits.

- Alignment and Gear Meshing: Ensure proper alignment and gear meshing between the sun gear, planet gears, and ring gear. Misalignment or improper gear engagement can cause excessive wear and damage to the gear system. Regularly check and adjust the gear alignment as needed.

- Proactive Repairs and Replacements: If any issues, such as worn teeth, damaged gear components, or abnormal vibrations, are detected during inspections or monitoring, take proactive measures to repair or replace the affected parts. Timely repairs can prevent further damage and improve the overall performance and reliability of the sun gears.

- Operating Conditions: Consider the operating conditions of the gear system, such as temperature, humidity, and environmental factors. Ensure that the sun gears are protected from excessive heat, moisture, contaminants, and corrosive substances that can adversely affect their performance and durability.

In summary, proper lubrication and maintenance of sun gears are critical for their optimal performance and longevity. Considerations include selecting the right lubricant, applying it correctly, inspecting the lubricant regularly, conducting routine inspections, monitoring torque and load, ensuring proper alignment and gear meshing, performing proactive repairs and replacements, and considering the operating conditions. Adhering to these considerations helps ensure reliable and efficient operation of sun gears in various mechanical systems.

What is the purpose of using a sun gear in mechanical applications?

The use of a sun gear in mechanical applications serves several important purposes. This central gear component plays a crucial role in achieving specific functionalities and benefits within gear systems. Here’s an explanation of the purpose of using a sun gear:

- Power Transmission: The primary purpose of a sun gear is to facilitate power transmission within gear systems. It acts as a central driver that receives power input, typically from an external source such as an engine or motor. The sun gear transfers torque to other gears, enabling the transmission of rotational motion and power throughout the system.

- Gear Ratio Control: Sun gears are instrumental in controlling the gear ratio within a gear system. By altering the size, number of teeth, and interaction with other gears such as planet gears and ring gears, the sun gear helps determine the overall gear ratio. This allows for the adjustment of rotational speed and torque output according to the specific requirements of the mechanical application.

- Torque Multiplication: In certain gear systems, a sun gear can be used to multiply torque. By employing a planetary gear arrangement, where the sun gear interacts with multiple planet gears and an outer ring gear, torque can be amplified. This torque multiplication capability of the sun gear is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Sun gears can also play a role in controlling the direction of power transmission within gear systems. In planetary gear arrangements, fixing or holding the sun gear while the ring gear or planet carrier is driven can result in different output directions, such as forward or reverse rotation. This directional control feature adds versatility to gear systems, allowing them to be utilized in various mechanical applications.

- Compact Design: The utilization of a sun gear in gear systems often enables a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions.

In summary, the purpose of using a sun gear in mechanical applications is to facilitate power transmission, control gear ratios, provide torque multiplication, offer directional control, and enable compact designs. The specific application and requirements of a mechanical system determine the selection and utilization of sun gears, ensuring efficient and reliable operation in various industries such as automotive, aerospace, industrial machinery, and more.

editor by CX 2023-09-28

China Professional Steel Metal Reduction Starter Shaft Spline Pinion Custom Precision Machine Transmission Wheel Planetary Sun Drive Spiral Helical Gear worm gear winch

Product Description

Click Here Get More Information

Our Advantages

Equipment

3-axis, 4-axis and full 5-axis processing equipment, CNC lathe, centering machine, turning and milling compound, wire cutting, EDM, grinding, etc

Processing

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

Materials

Aluminum, metal, steel, metal, plastic, metal, brass, bronze, rubber, ceramic, cast iron, glass, copper, titanium, metal, titanium, steel, carbon fiber, etc

Tolerance

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

Quality Assurance

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

Tolerance

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment |

Machining Workshop

Production Process

Quality Guarantee

Click Here Get Free Quotation

Application industry

CNC Machining Parts Can Be Used in Many Industry

Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries, Instruments & Meters, Office equipments, Home appliance, Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc

Areospace

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons, Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears,Differential Housing, Axle Shafts

Auto&Motorcycle

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons,Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears, Differential Housing, Axle Shafts

Energy

Drill Pipes and Casing, Impellers Casings, Pipe Control Valves, Shafts, Wellhead Equipment, Mud Pumps, Frac Pumps, Frac Tools,Rotor Shafts and disc

Robotics

Custom robotic end-effectors, Low-volume prototype, Pilot, Enclosures, Custom tooling, Fixturing

Medical Industry

Rotary Bearing Seal Rings for CHINAMFG Knife,CT Scanner Frames,Mounting Brackets,Card Retainers for CT Scanners,Cooling Plenums for CT Scanners,Brackets for CT Scanners,Gearbox Components,Actuators,Large Shafts

Home Appliances

Screws, hinges, handles, slides, turntables, pneumatic rods, guide rails, steel drawers

Certifications

FAQ

Q1. What kind of production service do you provide?

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Simple Assembly and Various Metal Surface Treatment.

Q2. How about the lead time?

Mould : 3-5 weeks

Mass production : 3-4 weeks

Q3. How about your quality?

♦Our management and production executed strictly according to ISO9001 : 2008 quality System.

♦We will make the operation instruction once the sample is approval.

♦ We will 100% inspect the products before shipment.

♦If there is quality problem, we will supply the replacement by our shipping cost.

Q4. How long should we take for a quotation?

After receiving detail information we will quote within 24 hours

Q5. What is your quotation element?

Drawing or Sample, Material, finish and Quantity.

Q6. What is your payment term?

Mould : 50% prepaid, 50% after the mould finish, balance after sample approval.

Goods : 50% prepaid, balance T/T before shipment.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Aerospace/ Marine/Automotive/Medical Equipments |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 0.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in renewable energy systems?

Sun gears can indeed be used in renewable energy systems, particularly in applications that involve the conversion and transmission of mechanical power. Let’s explore how sun gears can be utilized in different types of renewable energy systems:

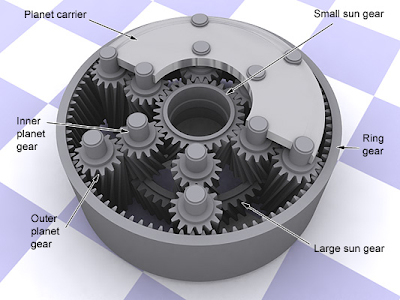

- Wind Turbines:

In wind turbines, sun gears can be employed as part of the gearbox mechanism. The gearbox is responsible for increasing the rotational speed of the wind turbine’s rotor to generate electricity efficiently. Sun gears, along with other gears such as planet gears and ring gears, can be used to achieve the desired gear ratios and torque amplification. By leveraging sun gears, wind turbines can convert the relatively low rotational speed of the rotor into the higher rotational speed required by the generator, which produces electricity.

- Solar Tracking Systems:

Sun gears can also play a role in solar tracking systems, which are used to maximize the energy generation of solar panels by orienting them towards the sun throughout the day. These systems often utilize gears to control the movement of the solar panels. Sun gears can be incorporated into the gear mechanism to enable precise tracking and adjustment of the solar panels’ position, ensuring optimal sunlight exposure and energy capture.

- Hydroelectric Power Plants:

In hydroelectric power plants, sun gears can be employed in the turbine and generator systems. These systems use the force of flowing or falling water to drive turbines, which, in turn, generate electricity. Sun gears can be part of the turbine’s gearbox, enabling the efficient conversion of the low-speed rotation of the turbine into the high-speed rotation required by the generator. By utilizing sun gears, hydroelectric power plants can enhance the power generation capabilities of the turbines.

- Wave and Tidal Energy Converters:

Wave and tidal energy converters harness the power of ocean waves and tides to generate electricity. Sun gears can be utilized in the transmission systems of these converters. They can help convert the slow, oscillating motion of the waves or tides into a higher rotational speed suitable for driving generators. By incorporating sun gears, these converters can optimize the energy extraction process and improve the efficiency of power generation.

- Geothermal Power Plants:

In geothermal power plants, sun gears can be used in various components of the energy conversion process. Geothermal power plants extract heat from the Earth’s interior to generate electricity. Sun gears can be employed in systems such as turbines and generators, where they facilitate the conversion of thermal energy into mechanical and electrical energy. By utilizing sun gears, geothermal power plants can enhance the efficiency and performance of the energy conversion systems.

In summary, sun gears can find applications in renewable energy systems such as wind turbines, solar tracking systems, hydroelectric power plants, wave and tidal energy converters, and geothermal power plants. By leveraging the functionality of sun gears, these systems can optimize power generation, increase efficiency, and contribute to the sustainable utilization of renewable energy sources.

What are the considerations for lubrication and maintenance of sun gears?

Proper lubrication and maintenance of sun gears are crucial for ensuring their optimal performance, longevity, and reliability. Sun gears, like other mechanical components, require appropriate lubrication to minimize friction, reduce wear, and prevent damage. Here are some considerations for lubrication and maintenance of sun gears:

- Lubrication:

Effective lubrication is essential for sun gears to operate smoothly and efficiently. Consider the following aspects:

- Lubricant Selection: Choose a lubricant that is specifically designed for gear applications. The lubricant should have the necessary viscosity, additives, and thermal stability to provide adequate lubrication and protection to the sun gears under the operating conditions.

- Proper Lubricant Application: Ensure that the lubricant is applied correctly to the sun gears. This can involve methods such as oil baths, oil mist systems, or grease application, depending on the specific gear system and its requirements. Follow the manufacturer’s guidelines or consult with lubrication experts for the appropriate lubrication technique.

- Regular Lubricant Inspection: Monitor the lubricant condition regularly to ensure its effectiveness and to detect any signs of contamination, degradation, or insufficient lubrication. Perform oil analysis or visual inspections as recommended by lubrication experts or equipment manufacturers.

- Maintenance:

Proper maintenance practices help keep sun gears in optimal working condition and extend their service life. Consider the following maintenance considerations:

- Regular Inspections: Conduct routine inspections of the sun gears to check for any signs of wear, damage, misalignment, or abnormal operating conditions. Inspections can help identify potential issues early, allowing for timely maintenance or repairs.

- Torque and Load Monitoring: Keep track of the torque and load applied to the sun gears. Ensure that the gear system is not subjected to excessive loads or overloading, as this can lead to premature wear and failure. Use appropriate monitoring techniques, such as load sensors or torque meters, to ensure the gear system operates within its designed limits.

- Alignment and Gear Meshing: Ensure proper alignment and gear meshing between the sun gear, planet gears, and ring gear. Misalignment or improper gear engagement can cause excessive wear and damage to the gear system. Regularly check and adjust the gear alignment as needed.