Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. Mechanical Transmission Parts Co., Ltd. is a professional manufacturer of mechanical transmission parts, founded in 1987. Our company is committed to standard roller sprocket, single row and multi-row sprocket, non-standard sprocket, gear, rack, bevel gear, sprocket, shaft, gear shaft and other products. We have passed ISO 9001 .Xihu (West Lake) Dis. company has a number of experienced engineers, involved in plHangZhou, testing, heat treatment, inspection, the use of strict and accurate testing methods. Our sprockets are widely used in agricultural machinery, stereoscopic garage, mining equipment, woodworking machinery, petroleum machinery and other industries. Implementation standards such as ANSI.BS, DIN.KANA, etc., can also be customized according to the drawing processing

Our products have won wide praise and trust from customers for their excellent quality. HangZhou Xihu (West Lake) Dis. mechanical transmission Parts Co., Ltd. adhere to the quality of survival, innovation and development, customer first business philosophy, dedicated to domestic and foreign customers service. We warmly welcome you to negotiate business with us.

Product Description

| Standard or Nonstandard | Standard | Application | Maqchinery | |

| Hardness | Hardened Tooth Surface | Material | C45 | |

| Specification | Various Sprockets | Pitch(PCD) | 1-10M | |

| Toothed Portion Shape | Spur Gear | Teeth | 10-60Z | |

| HS Code | 84839000 | Production Capacity | 100000 Pcs/Year |

Detailed Photos

Certifications

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3d drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you describe the interaction between sun gears and planet gears?

The interaction between sun gears and planet gears is a fundamental aspect of gear systems. Let’s delve into the details of this interaction:

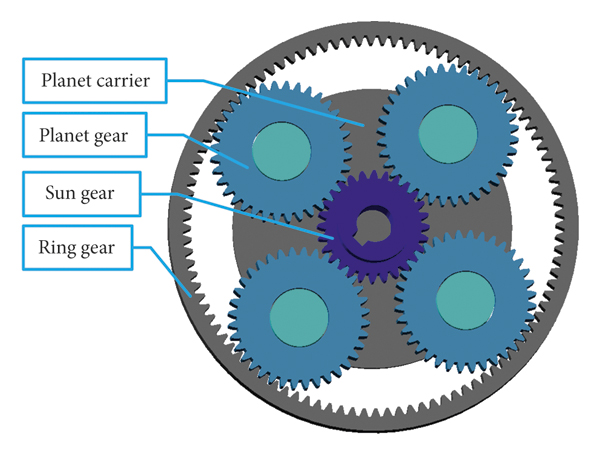

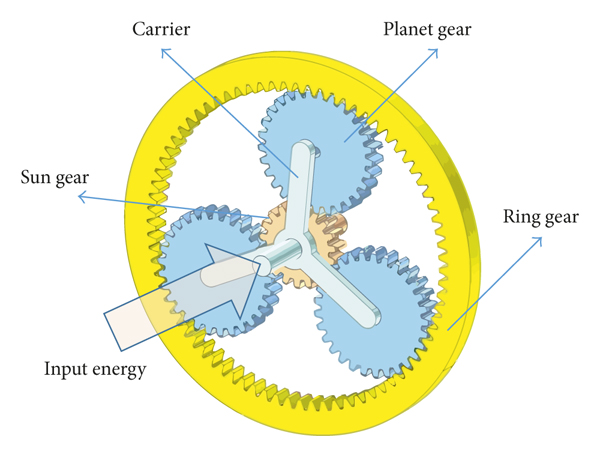

- Planetary Gear Systems:

The interaction between sun gears and planet gears primarily occurs in planetary gear systems. These systems consist of multiple planet gears that rotate around a central sun gear while meshing with an outer ring gear. This arrangement allows for various mechanical advantages and functionalities.

- Power Transmission:

The sun gear serves as the primary driver in a planetary gear system. When power is applied to the sun gear, it transmits rotational force to the planet gears. The planet gears, due to their meshing with both the sun gear and the ring gear, distribute the transmitted power evenly across all the gears.

As the sun gear rotates, the planet gears rotate in the opposite direction around the sun gear while also rotating around their own axes. This rotational movement of the planet gears, driven by the sun gear, plays a crucial role in power transmission within the gear system.

- Speed and Torque Ratios:

The interaction between the sun gear and planet gears affects the speed and torque ratios in a gear system. By choosing different sizes for the sun gear and planet gears, engineers can manipulate the gear ratios to achieve specific outcomes.

When the sun gear is larger than the planet gears, it results in a higher speed ratio. In this case, the sun gear rotates faster than the planet gears, leading to an output shaft or ring gear with increased rotational speed relative to the input shaft or sun gear.

Conversely, when the sun gear is smaller than the planet gears, it leads to a lower speed ratio. In this scenario, the sun gear rotates slower than the planet gears, resulting in an output shaft or ring gear with reduced rotational speed compared to the input shaft or sun gear.

Similarly, the interaction between the sun gear and planet gears affects the torque ratio. When the sun gear is larger than the planet gears, it amplifies the torque, resulting in higher output torque relative to the input torque. Conversely, when the sun gear is smaller, it reduces the torque, resulting in lower output torque compared to the input torque.

- Direction Reversal:

The interaction between the sun gear and planet gears also enables torque direction reversal in planetary gear systems. When the sun gear rotates in a specific direction, it imparts torque to the planet gears, causing them to rotate in the opposite direction around the sun gear.

This counterclockwise rotation of the planet gears, as driven by the sun gear, leads to the ring gear rotating in the opposite direction. By reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Mechanical Advantages:

The interaction between sun gears and planet gears offers several mechanical advantages. The distribution of torque across multiple planet gears allows for increased load-bearing capacity and improved system reliability. As each planet gear shares the load, the overall stress on individual gears is reduced, enhancing the system’s durability.

Moreover, the arrangement of sun gears and planet gears in a planetary gear system results in compact designs and high power density. The distributed power transmission and torque-sharing characteristics enable the system to handle higher loads while occupying minimal space.

In summary, the interaction between sun gears and planet gears in planetary gear systems is crucial for power transmission, achieving speed and torque ratios, enabling torque direction reversal, and providing mechanical advantages such as load distribution and compact designs. Understanding this interaction is essential for designing and optimizing gear systems in various applications.

Can sun gears be used in high-torque applications?

Sun gears can indeed be used in high-torque applications and are commonly employed in various mechanical systems that require substantial torque transmission. The design and characteristics of sun gears make them capable of handling significant torque loads. Here’s an explanation of why sun gears can be used in high-torque applications:

- Central Positioning: Sun gears are typically located at the center of planetary gear arrangements. This central positioning allows them to distribute torque to multiple planet gears, which then transfer the torque to the outer ring gear. The central position of the sun gear enables efficient torque transmission and load sharing among the gears, making it suitable for handling high-torque applications.

- Torque Amplification: The arrangement of sun gears in a planetary gear system allows for torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. In high-torque applications, this torque amplification capability of sun gears is advantageous as it allows for the multiplication of input torque, resulting in higher torque output.

- Sturdy Construction: Sun gears are designed to withstand high torque forces. They are usually made from durable materials such as hardened steel or other alloys with high tensile strength. This robust construction ensures that sun gears can effectively handle the transmitted torque without experiencing excessive wear or deformation.

- Load Distribution: The interaction between the sun gear, planet gears, and ring gear in a planetary gear system enables effective load distribution. By distributing the torque across multiple planet gears, the load is shared, reducing the stress on individual gears. This load distribution mechanism enhances the overall durability and torque-handling capacity of the gear system, making it suitable for high-torque applications.

- Customizable Gear Ratios: Sun gears in planetary systems allow for the customization of gear ratios. By changing the number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, the gear ratio can be tailored to meet specific application requirements. This flexibility in gear ratio control enables the optimization of torque output for high-torque applications.

In summary, sun gears can be effectively used in high-torque applications due to their central positioning, torque amplification capability, sturdy construction, load distribution mechanism, and customizable gear ratios. These characteristics make sun gears reliable and suitable for transmitting substantial torque in various mechanical systems.

What is the purpose of using a sun gear in mechanical applications?

The use of a sun gear in mechanical applications serves several important purposes. This central gear component plays a crucial role in achieving specific functionalities and benefits within gear systems. Here’s an explanation of the purpose of using a sun gear:

- Power Transmission: The primary purpose of a sun gear is to facilitate power transmission within gear systems. It acts as a central driver that receives power input, typically from an external source such as an engine or motor. The sun gear transfers torque to other gears, enabling the transmission of rotational motion and power throughout the system.

- Gear Ratio Control: Sun gears are instrumental in controlling the gear ratio within a gear system. By altering the size, number of teeth, and interaction with other gears such as planet gears and ring gears, the sun gear helps determine the overall gear ratio. This allows for the adjustment of rotational speed and torque output according to the specific requirements of the mechanical application.

- Torque Multiplication: In certain gear systems, a sun gear can be used to multiply torque. By employing a planetary gear arrangement, where the sun gear interacts with multiple planet gears and an outer ring gear, torque can be amplified. This torque multiplication capability of the sun gear is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Sun gears can also play a role in controlling the direction of power transmission within gear systems. In planetary gear arrangements, fixing or holding the sun gear while the ring gear or planet carrier is driven can result in different output directions, such as forward or reverse rotation. This directional control feature adds versatility to gear systems, allowing them to be utilized in various mechanical applications.

- Compact Design: The utilization of a sun gear in gear systems often enables a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions.

In summary, the purpose of using a sun gear in mechanical applications is to facilitate power transmission, control gear ratios, provide torque multiplication, offer directional control, and enable compact designs. The specific application and requirements of a mechanical system determine the selection and utilization of sun gears, ensuring efficient and reliable operation in various industries such as automotive, aerospace, industrial machinery, and more.

editor by CX 2023-09-08

China Hot selling Steel Metal Reduction Starter Shaft Spline Pinion Custom Precision Machine Wheel Transmission Planetary Sun Drive Spur Gear worm gear winch

Product Description

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

| Application: | Motor, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the safety considerations when working with sun gears in machinery?

Working with sun gears in machinery requires careful attention to safety to prevent accidents and ensure the well-being of operators. Here are some important safety considerations when working with sun gears:

- Training and Knowledge:

Operators and maintenance personnel should receive proper training and have a thorough understanding of the machinery’s operation and the specific risks associated with working with sun gears. This includes knowledge of safety procedures, maintenance protocols, and the use of personal protective equipment (PPE).

- Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on machinery involving sun gears, it is essential to follow lockout/tagout procedures. These procedures involve isolating the machinery from its power source and ensuring that it cannot be accidentally energized during maintenance. Lockout/tagout procedures help prevent unexpected movements of the gears, reducing the risk of injury.

- Personal Protective Equipment (PPE):

Appropriate personal protective equipment should be worn when working with sun gears. This may include safety glasses, gloves, protective clothing, and hearing protection, depending on the specific hazards present. PPE helps protect operators from potential injuries caused by flying debris, contact with moving parts, and excessive noise.

- Machine Guards:

Machine guards should be in place to prevent accidental contact with the sun gears during operation. Guards can be physical barriers, such as covers or enclosures, that restrict access to the gears. They act as a protective barrier and reduce the risk of entanglement or injury caused by accidental contact with rotating or moving parts.

- Maintenance and Inspection:

Regular maintenance and inspection of machinery, including sun gears, are crucial for identifying potential issues and preventing malfunctions or failures. Maintenance tasks should be carried out following manufacturer guidelines and recommendations. Inspection of gears should include checking for signs of wear, proper lubrication, and alignment.

- Proper Handling and Lifting:

When handling sun gears or transporting them within a facility, proper lifting techniques and equipment should be used. Sun gears can be heavy and require appropriate lifting devices, such as cranes or hoists, to avoid strain or injuries. Operators should also ensure that gears are securely fastened or stored to prevent them from falling or causing accidents.

- Risk Assessment:

A comprehensive risk assessment should be conducted to identify hazards associated with sun gears and their machinery. The assessment should consider factors such as gear size, rotational speed, pinch points, and potential for entanglement. Based on the assessment, appropriate safety measures and controls should be implemented to mitigate identified risks.

- Emergency Procedures:

Clear emergency procedures should be established and communicated to all personnel working with sun gears. These procedures should include protocols for responding to accidents, injuries, or equipment malfunctions. Operators should be familiar with emergency shutdown procedures and know how to safely stop the machinery in case of an emergency.

By adhering to these safety considerations, operators and maintenance personnel can minimize the risk of accidents and promote a safe working environment when working with sun gears in machinery.

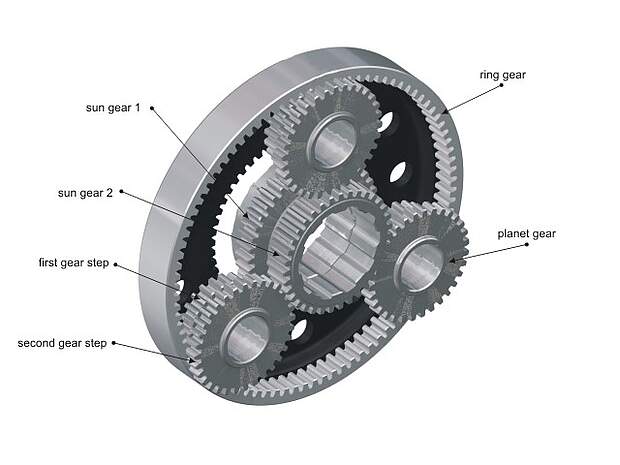

How do you calculate gear ratios involving a sun gear in planetary systems?

Calculating gear ratios in planetary systems involving a sun gear requires considering the number of teeth on the gears and their arrangement. Understanding the calculation process helps in determining the gear ratio and predicting the rotational relationship between the input and output gears. Here’s an explanation of how to calculate gear ratios involving a sun gear in planetary systems:

- Step 1: Identify the Gears: In a planetary system, identify the gears involved, namely the sun gear, planet gears, and ring gear. The sun gear is the gear at the center, surrounded by the planet gears, which in turn engage with the outer ring gear.

- Step 2: Count the Teeth: Count the number of teeth on each gear. The sun gear, planet gears, and ring gear all have a specific number of teeth. Let’s denote these as Ts (sun gear teeth), Tp (planet gear teeth), and Tr (ring gear teeth).

- Step 3: Determine the Gear Ratio: The gear ratio in a planetary system involving a sun gear is calculated using the following formula:

Gear Ratio = (Tp + Tr) / Ts

- Step 4: Interpret the Gear Ratio: The calculated gear ratio represents the rotational relationship between the input (sun gear) and output (ring gear) gears. For example, if the gear ratio is 2:1, it means that for every two revolutions of the sun gear, the ring gear completes one revolution in the opposite direction.

- Step 5: Adjust for Multiple Planet Gears or Fixed Components: In some cases, planetary systems may involve multiple planet gears or fixed components. The presence of multiple planet gears affects the gear ratio, and the inclusion of fixed components alters the gear engagement and behavior. These factors may require additional calculations or adjustments to accurately determine the gear ratio.

In summary, calculating gear ratios involving a sun gear in planetary systems necessitates identifying the gears, counting the teeth on each gear, and applying the appropriate formula. The resulting gear ratio provides insights into the rotational relationship between the sun gear and the ring gear. It’s important to consider any additional elements, such as multiple planet gears or fixed components, that may influence the gear ratio calculation.

What is a sun gear and how does it function in gear systems?

A sun gear is a fundamental component in gear systems, particularly in planetary gear arrangements. It plays a crucial role in determining the overall gear ratio and power distribution within the system. Here’s an explanation of what a sun gear is and how it functions:

A sun gear is a central gear in a planetary gear set. It is typically located at the center of the gear arrangement and is surrounded by other gears, known as planet gears, as well as an outer ring gear, also called a ring gear or annulus.

The primary function of the sun gear is to transfer torque and provide the driving force in a planetary gear system. Here’s how it functions:

- Power Input: The sun gear receives power input from an external source, such as an engine or motor. It is directly connected to the input shaft and receives rotational motion and torque.

- Planet Gear Engagement: The sun gear engages with multiple planet gears, which are smaller gears that surround the sun gear and mesh with both the sun gear and the ring gear. The planet gears rotate around their own axes while also revolving around the sun gear.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the ring gear. The relative sizes of the sun gear, planet gears, and ring gear determine the gear ratio and the distribution of power within the system.

- Gear Ratio Variation: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This allows gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Directional Control: In some gear systems, the sun gear can also serve as a means of controlling the direction of power transmission. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation.

In summary, the sun gear is a central gear in planetary gear systems, responsible for receiving power input, engaging with planet gears, distributing torque to the ring gear, and determining the overall gear ratio. Its function is crucial in achieving different speed and torque combinations, as well as controlling the direction of power transmission within gear systems.

editor by CX 2023-09-07

China 1st Planetary Sun Gear Carrier Assy Swing Final Drive Gear for Komatsu PC200-7 Excavator planetary gearbox dc motor

Condition: New

Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Retail

Showroom Location: None

Video outgoing-inspection: Not Available

Machinery Test Report: Not Available

Marketing Type: New Product 2571

Warranty: 6 Months, 6 Montns

Application: Replacement

Product name: Planet Carrier Assy

Quality: High-Quality

Delivery time: 1-3 Days/No

Material: Steel

Apply to: Swing gearbox

Packing: Wooden Case

Color: Black

After-sales service provided: Online support

Packaging Details: Wooden Case

Port: HuangPu

Products Description

| Title | 1st Planetary Sun Gear Carrier Assy Swing Final Drive Gear for CZPT PC200-7 Excavator |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Other |

| Machine model | PC200-7 |

| Compatible Brand | For Komatsu |

| Packing | Wooden Case |

| Customized support | OEM |

| Application | Excavator reducer |

Planetary Gearbox Basics

If you’re in the market for a new Planetary Gearbox, you’ve come to the right place. There’s more to these mechanical wonders than just their name. Learn about Spur gears, helical gears, and various sizes. After you’ve read this article, you’ll know exactly what to look for when shopping for a new one. And you’ll also be able to avoid common mistakes made by amateur mechanics.

Wheel drive planetary gearboxes

Planetary gearboxes have numerous benefits over conventional gearboxes. Their compact design is advantageous for servo functions. Their lubrication is a key feature to maintain smooth operation and avoid damage to the gears. Some manufactures use CZPT to ensure proper functioning. These gearboxes have nearly three times the torque of traditional gearboxes while remaining compact and low in mass.

The planetary gears are made of three different types. Each type has an input and output shaft. The input and output shafts are usually coaxially arranged. The input and output shafts are connected to each other via a carrier. The carrier rotates with the planetary gears. The sun gear is the input gear and is typically 24 teeth in diameter. The outer gears are connected to the sun gear via rings of gears that are mounted around the sun gear.

Planetary gearboxes are also used in wheeled and tracked vehicles. They are also used in winch systems, which lift and lower loads. Typical applications include heavy machinery, such as cranes and earthmovers. Wheel drives are also widely used in municipal and agricultural vehicles, as well as material handling vehicles. The wheel drive is typically mounted directly into the wheel rim. A wheel drive may be fitted into two, three, or even four wheels.

A planetary gear set may be used in stages to provide different transmission rates. In order to choose the right gearbox for your application, consider the torque, backlash, and ratio you need. Then, consider the environment where the gearbox is used. Depending on its location, it might need to be protected from weather, water, and other elements. You can find a wide range of different sizes in the market.

Spur gears

There are two basic types of gearheads: planetary and spur gearheads. Each has its advantages and disadvantages depending on the application. This article will discuss the differences between these two types of gearheads. Spur gearheads are commonly used for transmission applications, while planetary gearheads are more widely used for motors. Spur gearheads are less expensive to produce than planetary gearheads, and they are more flexible in design.

There are many different types of spur gears. Among them, a 5:1 spur gear drive ratio means that the sun gear must rotate five times per revolution of the output carrier. The desired number of teeth is 24. In metric systems, the spur gears are referred to as mm and the moon gears as modules. Spur gears are used in many different types of applications, including automotive and agricultural machinery.

A planetary geartrain is a combination of ring and spur gears, which mesh with each other. There are two kinds of planetary geartrains: simple planetary gears and compound planetary gears. Spur gears are the most common type, with a sun gear and ring gear on either side of the sun. Simple planetary gears feature a single sun and ring gear, while compound planetary gears use multiple planets.

A planetary gearbox consists of two or more outer gears, which are arranged to rotate around the sun. The outer ring gear meshes with all of the planets in our solar system, while the sun gear rotates around the ring gear. Because of this, planetary gearboxes are very efficient even at low speeds. Their compact design makes them a desirable choice for space-constrained applications.

Helical gears

A planetary helical gearbox has two stages, each with its own input speed. In the study of planetary helical gear dynamics, the base circle radius and full-depth involute teeth are added to the ratio of each gear. The tangential position of the planets affects the dynamic amplifications and tooth forces. The tangential position error is an important factor in understanding the dynamic behaviour of helical planetary gears.

A helical gearbox has teeth oriented at an angle to the shaft, making them a better choice than spur gears. Helical gears also operate smoothly and quietly, while spur gears generate a thrust load during operation. Helical gears are also used in enclosed gear drives. They are the most common type of planetary gearbox. However, they can be expensive to produce. Whether you choose to use a helical or spur gearbox depends on the type of gearbox you need.

When choosing a planetary gear, it is important to understand the helix angle of the gear. The helix angle affects the way the planetary gears mesh, but does not change the fundamentals of planetary phasing. In each mesh, axial forces are introduced, which can either cancel or reinforce. The same applies to torques. So, if the ring gear is positioned at an angle of zero, helical gears will increase the axial forces.

The number of teeth on the planets is a variable parameter that must be considered in the design phase. Regardless of how many teeth are present, each planet must have a certain amount of tooth spacing to mesh properly with the ring or sun. The tip diameter is usually unknown in the conceptual design stage, but the pitch diameter may be used as an initial approximation. Asymmetrical helical gears may also cause undesirable noise.

Various sizes

There are several sizes and types of planetary gearboxes. The planetary gear sets feature the sun gear, the central gear, which is usually the input shaft, and the planet gears, which are the outer gears. A carrier connects the planet gears to the output shaft. The primary and secondary features of the planetary gearbox are important factors to consider. Besides these, there are other things to consider, such as the price, delivery time, and availability around the world. Some constructors are quicker than others in responding to inquiries. While others may be able to deliver every planetary gearbox out of stock, they will cost you more money.

The load share behavior of a planetary gearbox is comparable to that of a spur or a helical gearbox. Under low loads, individual gear meshes are slightly loaded, while other components have minimal deflections. In general, load sharing behaviour is affected mostly by assembly and manufacturing deviations. In this case, the elastic deflections help balance these effects. The load-sharing behavior of a planetary gearbox improves when the load increases.

Planetary gearboxes come in different sizes. The most common size is one with two or three planets. The size and type of the gears determine the transmission rate. Planetary gear sets come in stages. This gives you multiple transmission rate choices. Some companies offer small planetary gearboxes, while others offer larger ones. For those with special applications, make sure you check the torque, backlash, and ratio.

Whether the power is large or small, the planetary gearbox should be matched to the size of the drive. Some manufacturers also offer right-angle models. These designs incorporate other gear sets, such as a worm gear stage. Right-angle designs are ideal for situations where you need to vary the output torque. When determining the size of planetary gearboxes, make sure the drive shafts are lined up.

Applications

This report is designed to provide key information on the Global Applications of Planetary Gearbox Market, including the market size and forecast, competitive landscape, and market dynamics. The report also provides market estimates for the company segment and type segments, as well as end users. This report will also cover regional and country-level analysis, market share estimates, and mergers & acquisitions activity. The Global Applications of Planetary Gearbox Market report includes a detailed analysis of the key players in the market.

The most common application of a planetary gearbox is in the automobile industry, where it is used to distribute power between two wheels in a vehicle’s drive axle. In a four-wheel-drive car, this system is augmented by a centre differential. In hybrid electric vehicles, a summation gearbox combines the combustion engine with an electric motor, creating a hybrid vehicle that uses one single transmission system.

In the Global Industrial Planetary Gearbox Market, customer-specific planetary gears are commonly used for automated guided vehicles, intra-logistics, and agricultural technology. These gears allow for compact designs, even in tight spaces. A three-stage planetary gear can reach 300 Nm and support radial loads of 12 kN. For receiver systems, positioning accuracy is critical. A two-stage planetary gearbox was developed by CZPT. Its internal gear tension reduces torsional backlash, and manual controls are often used for high-quality signals.

The number of planetary gears is not fixed, but in industrial applications, the number of planetary gears is at least three. The more planetary gears a gearbox contains, the more torque it can transmit. Moreover, the multiple planetary gears mesh simultaneously during operation, which results in high efficiency and transmittable torque. There are many other advantages of a planetary gearbox, including reduced maintenance and high speed.

editor by Cx 2023-07-13

China OEM Less price Optical Disk Driver reducer metal planetary gearbox planetary gearbox clutch

Product Description

Less price Optical Disk Driver reducer metal planetary gearbox

Main Features

1.OEM/ODM 36mm Planetary reducer plus TEC3650&3640 brushless motor

2.Small size dc gear motor with low speed and big torque

3.36mm gear motor provide 3.0Nm torque max and more reliable

4.Suitable to small diameter, low noise and big torque application

5.Reduction ratio:4,14,19,27,51,71,100,139,189,264,369,516,720

| Motor model no. | Rated voltage | No-load speed | No-load current | Rated speed | Rated torque | Rated current | Output power | Stall torque | Stall current |

| VDC | r/min | mA | r/min | g.cm | mA | W | g.cm | A | |

| TFC3650-2465 | 24 | 6500 | 200 | 5400 | 200 | 1000 | 11.5 | 1150 | 2.6 |

| TFC3650-2440 | 24 | 4000 | 120 | 3200 | 200 | 600 | 6.6 | 1000 | 2.0 |

| TFC3650-1245 | 12 | 4500 | 150 | 3500 | 230 | 880 | 8.3 | 820 | 2.5 |

Gear motor technical data : GMP36-TEC3650-2465-xxx

| Reduction ratio | 4 | 19 | 51 | 100 | 139 | 189 | 264 | 369 | 516 | 720 |

| Length mm | 26 | 33.5 | 40.5 | 40.5 | 40.5 | 47.5 | 47.5 | 47.5 | 47.5 | 47.5 |

| No-load speed rpm | 1600 | 340 | 125 | 65 | 45 | 33 | 23 | 17 | 12 | 9 |

| Rated speed rpm | 1300 | 280 | 100 | 53 | 38 | 28 | 20 | 14.5 | 10 | 7.5 |

| Rated torque kg.cm | 0.6 | 2.7 | 6.0 | 12 | 16.6 | 22.5 | 30 | 30 | 30 | 30 |

| Max.momentary tolerance torque kg.cm | 3.7 | 15 | 35 | 69 | 70 | 70 | 70 | 70 | 70 | 70 |

Gear motor technical data : GMP36-TEC3650-2440-xxx

| Reduction ratio | 4 | 19 | 51 | 100 | 139 | 189 | 264 | 369 | 516 | 720 |

| Length mm | 26 | 33.5 | 40.5 | 40.5 | 40.5 | 47.5 | 47.5 | 47.5 | 47.5 | 47.5 |

| No-load speed rpm | 950 | 200 | 75 | 40 | 28 | 20 | 15 | 10 | 7.5 | 5.5 |

| Rated speed rpm | 750 | 160 | 60 | 30 | 22 | 16 | 12 | 8 | 6 | 4.5 |

| Rated torque kg.cm | 0.6 | 2.7 | 6.0 | 12 | 16.6 | 22.5 | 30 | 30 | 30 | 30 |

| Max.momentary tolerance torque kg.cm | 3.7 | 15 | 35 | 69 | 70 | 70 | 70 | 70 | 70 | 70 |

Gear motor technical data : GMP36-TEC3650-1245-xxx

| Reduction ratio | 4 | 19 | 51 | 100 | 139 | 189 | 264 | 369 | 516 | 720 |

| Length mm | 26 | 33.5 | 40.5 | 40.5 | 40.5 | 47.5 | 47.5 | 47.5 | 47.5 | 47.5 |

| No-load speed rpm | 1050 | 230 | 85 | 44 | 32 | 23 | 17 | 12 | 9 | 6 |

| Rated speed rpm | 875 | 185 | 68 | 35 | 25 | 18 | 13 | 10 | 7 | 5 |

| Rated torque kg.cm | 0.7 | 3.0 | 7.0 | 14 | 19 | 24 | 30 | 30 | 30 | 30 |

| Max.momentary tolerance torque kg.cm | 2.6 | 11 | 25 | 50 | 68 | 70 | 70 | 70 | 70 | 70 |

Related product

Product Application

| Other Applications: | |

| Business Machines: | ATM, Copiers and Scanners, Currency Handling, Point of Sale, Printers, Vending Machines. |

| Food and Beverage: | Beverage Dispensing, Hand Blenders, Blenders, Mixers, Coffee Machines, Food Processors, Juicers, Fryers, Ice Makers, Soy Bean Milk Makers. |

| Home Entertainment and Gaming: | Gaming Machines, Video Games, Optical Disk Drives, RC and Power Toys. |

| Home Technologies: | Home Ventilation, Air Purifiers and Dehumidifiers, Range Hoods, Washers and Dryers, Refrigerators, Dishwashers, Floor Care, Whirlpool and Spa, Showers, Smart Metering, Coffee Machines. |

| Lawn and Garden: | Lawn Mowers, Snow Blowers, Trimmers, Leaf Blowers. |

| Personal Care: | Hair Cutting, Hair Care, Massagers. |

| Power Tools: | Drills and Drivers, Sanders, Grinders, Polishers, Saws. |

| Camera and Optical: | Video, Cameras, Projectors. |

Packing & Delivery

Packaging: single carton packing, 100 pieces per box.

Shipping time:

DHL: 3-5 working days ;

UPS: 5-7 working days;

TNT: 5-7 working days;

FedEx: 7-9 working days;

EMS: 12-15 working days;

China Post: Depends on ship to which country;

Sea: Depends on ship to which country

Our company

TT Motor (HK) Industrial Co., Ltd. has been specializing in micro motors, gear motors and their respective parts since 2000.

Our products are widely used in entertainment systems, automobiles, home and industrial appliances and tools and many others. Our products are dependable and long-lasting, and backed by years of experience. We export 98% of our output worldwide.

By leveraging our hard-won reputation for honesty, dependability and quality, TT aims to continue as a pioneer in the sales overseas by seeking global partners. If your company is an end-user of micro-motors, a distributor or an agent, please contact us. We look forward to being able to work together with you in the near future.

Certifications

FAQ

Q: How to order?

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → CZPT contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

Q: How about Sample order?

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it would be refund when you place formal order.

Q: Which shipping way is avaliable?

A: DHL, UPS, FedEx, TNT, EMS, China Post,Sea are available.The other shipping ways are also available, please contact us if you need ship by the other shipping way.

Q: How long is the deliver?

A: Devliver time depends on the quantity you order. usually it takes 15-25 working days.

Q: My package has missing products. What can I do?

A: Please contact our support team and we will confirm your order with the package contents.We apologize for any inconveniences.

Q: How to confirm the payment?

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

| Application: | Industrial, Car, Power Tools |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | Permanent Magnet |

| Function: | Totally Enclosed |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 18/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Planetary Gearbox Advantages and Disadvantages

A planetary gearbox is a type of mechanical drive with a single output shaft. They are suitable for both clockwise and counterclockwise rotations, have less inertia, and operate at higher speeds. Here are some advantages and disadvantages of this type of gearbox. Let us see what these advantages are and why you should use them in your applications. Listed below are some of the benefits of planetary gearboxes.

Suitable for counterclockwise and clockwise rotation

If you want to teach children about the clock hands, you can buy some resources for counterclockwise and asymmetrical rotation. These resources include worksheets for identifying degrees of rotation, writing rules for rotation, and visual processing. You can also use these resources to teach angles. For example, the translation of shapes activity pack helps children learn about the rotation of geometric shapes. Similarly, the visual perception activity sheet helps children understand how to process information visually.

Various studies have been done to understand the anatomical substrate of rotations. In a recent study, CZPT et al. compared the position of the transitional zone electrocardiographically and anatomically. The authors found that the transitional zone was normal in nine of 33 subjects, indicating that rotation is not a sign of disease. Similarly, a counterclockwise rotation may be caused by a genetic or environmental factor.

The core tip data should be designed to work in both clockwise and counterclockwise rotation. Counterclockwise rotation requires a different starting point than a clockwise rotation. In North America, star-delta starting is used. In both cases, the figure is rotated about its point. Counterclockwise rotation, on the other hand, is done in the opposite direction. In addition, it is possible to create counterclockwise rotation using the same gimbal.

Despite its name, both clockwise and counterclockwise rotation requires a certain amount of force to rotate. When rotating clockwise, the object faces upwards. Counterclockwise rotation, on the other hand, starts from the top position and heads to the right. If rotating in the opposite direction, the object turns counterclockwise, and vice versa. The clockwise movement, in contrast, is the reverse of counterclockwise rotation.

Has less inertia

The primary difference between a planetary gearbox and a normal pinion-and-gear reducer is the ratio. A planetary gearbox will produce less inertia, which is an important advantage because it will reduce torque and energy requirements. The ratio of the planetary gearbox to its fixed axis counterpart is a factor of three. A planetary gearbox has smaller gears than a conventional planetary, so its inertia is proportional to the number of planets.

Planetary gears are less inertia than spur gears, and they share the load across multiple gear teeth. This means that they will have low backlash, and this is essential for applications with high start-stop cycles and frequent rotational direction changes. Another benefit is the high stiffness. A planetary gearbox will have less backlash than a spur gearbox, which means that it will be more reliable.

A planetary gearbox can use either spur or helical gears. The former provides higher torque ratings while the latter has less noise and stiffness. Both types of gears are useful in motorsports, aerospace, truck transmissions, and power generation units. They require more assembly time than a conventional parallel shaft gear, but the PD series is the more efficient alternative. PD series planetary gears are suitable for many applications, including servo and robotics.

In contrast, a planetary gear set can have varying input speed. This can affect the frequency response of the gearset. A mathematical model of the two-stage planetary gears has non-stationary effects and correlates with experimental findings. Fig. 6.3 shows an addendum. The dedendum’s minimum value is approximately 1.25m. When the dedendum is at its smallest, the dedendum has less inertia.

Offers greater reliability

The Planetary Gearbox is a better option for driving a vehicle than a standard spur gearbox. A planetary gearbox is less expensive, and they have better backlash, higher load capacity, and greater shock loads. Unlike spur gearboxes, however, mechanical noise is virtually nonexistent. This makes them more reliable in high-shock situations, as well as in a wide range of applications.

The Economy Series has the same power density and torque capacity of the Precision Helical Series, but it lacks the precision of the latter. In contrast, Economy Series planetary gearboxes feature straight spur planetary gearing, and they are used in applications requiring high torque. Both types of gearboxes are compatible with NEMA servo motors. If torque density is important, a planetary gearbox is the best choice.

The Dispersion of External Load: The SSI model has been extensively used to model the reliability of planetary gear systems. This model takes the contact force and fatigue strength of the system as generalized stress and strength. It also provides a theoretical framework to evaluate the reliability of planetary gear systems. It also has many other advantages that make it the preferred choice for high-stress applications. The Planetary Gearbox offers greater reliability and efficiency than traditional rack and pinion gear systems.

Planetary gearing has greater reliability and compact design. Its compact design allows for wider applications with concerns about space and weight. Additionally, the increased torque and reduction makes planetary gearboxes an excellent choice for a wide variety of applications. There are three major types of planetary gearboxes, each with its own advantages. This article describes a few of them. Once you understand their workings, you will be able to choose the best planetary gearbox for your needs.

Has higher operating speeds

When you look at planetary gearboxes, you might be confused about which one to choose. The primary issue is the application of the gearbox. You must also decide on secondary factors like noise level, corrosion resistance, construction, price, and availability worldwide. Some constructors work faster than others and deliver the gearboxes on the same day. However, the latter ones often deliver the planetary gearbox out of stock.

Compared to conventional gearboxes, a planetary gearbox can run at higher speeds when the input speed fluctuates. However, these gears are not very efficient in high-speed applications because of their increased noise levels. This makes planetary gears unsuitable for applications involving a great deal of noise. That is why most planetary gears are used in small-scale applications. There are some exceptions, but in general, a planetary gearbox is better suited for applications with higher operating speeds.

The basic planetary gearbox is a compact alternative to normal pinion-and-gear reducers. They can be used in a wide variety of applications where space and weight are concerns. Its efficiency is also higher, delivering 97% of the power input. It comes in three different types based on the performance. A planetary gearbox can also be classified as a worm gear, a spur gear, or a sprocket.

A planetary gearhead has a high-precision design and can generate substantial torque for their size. It also reduces backlash to two arc-min. Additionally, it is lubricated for life, which means no maintenance is needed. It can fit into a small machine envelope and has a small footprint. Moreover, the helical crowned gearing provides fast positioning. A sealed gearbox prevents abrasive dust from getting into the planetary gearhead.

Has drawbacks

The design of a planetary gearbox is compact and enables high torque and load capability in a small space. This gear arrangement also reduces the possibility of wear and tear. Planet gears are arranged in a planetary fashion, allowing gears to shift under load and a uniform distribution of torque. However, some disadvantages of planetary gears must be considered before investing in this gearbox.

While the planetary gearbox is a high precision motion-control device, its design and maintenance requirements are a concern. The bearing load is high, requiring frequent lubrication. Also, they are inaccessible. Despite these drawbacks, planetary gearboxes are suitable for a variety of tasks. They also have low backlash and high torsional stiffness, making them excellent choices for many applications.

As a result, the speed of a planetary gearbox varies with load and speed. At lower ratios, the sun gear becomes too large in relation to the planet gears. As the ratio increases, the sun gear will become too low, reducing torque. The planetary gears also reduce their torque in high-speed environments. Consequently, the ratio is a crucial consideration for planetary gearbox condition monitoring.

Excess drag may result from out-of-tolerance components or excessive lubrication. Drag should be measured both in directions and be within acceptable ranges. Grease and oil lubrication are two common planetary gearbox lubricants, but the choice is largely dependent on your application. While grease lubricates planetary gears well, oil needs maintenance and re-lubrication every few thousand hours.

editor by CX 2023-07-13

China 13mm 3.7v coreless motor with gearbox electric tool motor with planetary gear for dental myoelectric prosthesis compact planetary gearbox

Warranty: 3months-1year

Model Number: 1332RG

Usage: BOAT, Car, Electric Bicycle, FAN, Home Appliance, electric machine

Type: Micro Motor

Torque: 22-32 mNm (rated)

Construction: Permanent Magnet

Commutation: Brushless

Protect Feature: Explosion-proof

Speed(RPM): 420-7 Email: [email protected] [email protected]

What is a Planetary Gearbox?

A planetary gearbox is a mechanical device in which the teeth of a planet mesh with the teeth of its sun or ring. The number of teeth and the spacing of planets will determine whether the teeth mesh correctly. In this article, we will learn more about planetary gearboxes. Besides understanding their working, you can also learn how to design your own. Here are some examples:

planetary gearboxes

If your car has an automatic transmission, then a planetary gearbox is the type you have. It is possible to find out if you have this type of gearbox by consulting the owner’s manual, calling the service department of your car’s manufacturer, or conducting a search using your favorite search engine. However, planetary gears are more complex and have many more components than standard gearboxes. The following information will explain more about this type of gearbox.

Planetary gearboxes use three different gear types to transmit torque. The sun gear sits in the center of the gear assembly, while the other gears rotate around it. A carrier connects the two gears, and is designed to set the spacing between them. When the gears are rotated, the carrier will spin, enabling the entire assembly to work together. The carrier also incorporates the output shaft. For this gearbox to work effectively, it must meet the application’s requirements.

There are three main types of planetary gearboxes: the basic model is highly efficient and transmits 97% of the power input. The earliest models are not complex, but they do have some key differences. Some of these differences make them ideal for various applications. For example, a planetary gearbox can operate in alternating and continuous operation, with the output support having internal grooving. Some designs have more than one output shaft, allowing the user to choose the configuration and torque that is best for their application.

One of the main differences between a planetary gearbox and a conventional one is the way the planetary parts move. A planetary gearbox may have multiple axes for increased torque. A planetary gearbox can provide a torque up to 113,000 N.m. by rotating its maximum teeth simultaneously. They are the ideal choice for space-constrained applications. For instance, a car with small spaces can install one with ease.

A planetary gearbox’s gear ratio is determined by the ratio of the sun gear to the ring gear. The number of teeth on the sun gear is a way to adjust the gear ratio. Smaller sun gears result in larger planetary gear ratios, while larger ones cause a decrease in torque. The ratio between planetary gears ranges from 3:1 to 10:1, with the lowest ratio being three. The greatest possible ratio is 10:1.

A planetary gearbox has many benefits. The compact design makes them a more efficient choice for small motors and is advantageous for servo functions. Planetary gearboxes have low inertia, which is an important factor, especially in servo applications, since the inertia of the gearbox adds to the motor’s load inertia. The planetary gearboxes are typically lubricated with grease or oil, so you don’t need to worry about re-lubrication or maintenance.

planetary gearboxes with output shaft

The advantages of planetary gearboxes are numerous. They are widely used in many applications, from automobiles to medical equipment, goods & personnel lifts to machine tools. They are also used in derrick & dockyard cranes and slewing drives. These gearboxes are available in various sizes and shapes, ranging from small to extremely large. There are many different types, and each is designed to suit its intended use.

The LP generation 3 gearhead series combines maximum quality with economic precision in a low-backlash planetary gearbox. The output shaft version is especially suited for high-speed, highly dynamic cyclic operation. Another version is the SP+ HIGH SPEED. The SP+ high-speed version is designed to achieve maximum speeds while in continuous operation. If you need a planetary gearbox with an output shaft, look no further. It is the best choice for many applications.

As the name suggests, a planetary gearbox incorporates planetary parts and an output shaft. The outer gears (also called the planetary gears) are connected by a carrier to the output shaft. The carrier is then connected to the output shaft by a ring. There are two or more planetary gears inside the planetary gearbox. Each gear is connected to a carrier, which is connected to the output shaft.

An epicyclic planetary gear train can be assembled so that the planet gear rolls around the sun gear. In the wheel drive planetary gearbox, the planetary gears are grouped over the housing to optimize the size and weight of the system. The planetary gear train can handle torques as high as 332,000 N.m., with the ring gear being fixed while the sun gear is movable.

Another advantage of a planetary gearbox is that it uses many teeth at once. This allows for high speed reduction and high torque transmission, and it is extremely compact. Planetary gearboxes with output shaft are ideal for space-constrained applications. Their compact size and minimal weight make them a popular choice in many industries. They are also known as epicyclic gears and are used in many different types of machines.

A planetary gearbox can have three components. A central sun gear, an outer ring known as the inner gear, and an output shaft. These three components are linked by a carrier. The carrier rotates so that the input and output gears are in sync. They also have a standard gap between the gears. The carrier also acts as the output shaft. They can be used to create small machines, such as a bicycle acceleration hub.

planetary gearboxes with integer number of teeth

When designing a planetary gearbox, one must determine the amount of tooth count. This figure is known as the mesh load factor Kg, and is based on the normal tooth forces that are generated in each mesh. The number of planets, the error in the gear design, and the rigidity of the housing all affect Kg. Depending on the type of application, Kg can be calculated by using different standards.

In a typical planetary gearbox, the ratio is an integer number, and the lowest is 3:1. At a ratio of 10, the sun gear is too large and the sun wheel is too low to provide a sufficient amount of torque. In most cases, the ratio is an integer value, and the teeth are evenly spaced. The gear mesh is then balanced to grade 2. The carrier is measured three-dimensionally to detect the accuracy of the planet pin hole in the carrier.

In the simplest case, each planetary gear mesh produces a dynamic signal at its mesh frequency. These signals can cancel or reinforce in various ways. A helix angle, however, introduces axial forces into the gear mesh, which can be cancelled or reinforced in the same way as torques. As the helix angle is an integer number, this planetary gear model does not necessarily require infinite precision.

The resulting motion period is measured in rotational angles. This figure can be used to determine fault diagnosis and calculate the minimum data length required. It can also be used to calculate the kinematic motion of a faulty planet gear tooth. It is important to note that fault-mesh motion is not instantaneous, and therefore, it requires a sufficient amount of time to fully mesh a faulty planet gear.

The load-share factor is similar to that of spur and helical gearboxes, and can be used to calculate dynamic load sharing. When the load share factor is low, the individual gear meshes are slightly loaded. Deflections can vary, especially with high-precision gears. Therefore, the design process should incorporate the tolerance chain. This will ensure the correct ratio of gear mesh.

A planetary gearbox is a type of planetary gear system that is used in motors. It has a sun gear at the center and a set of outer gears. Each gear turns according to its axis around the sun. They are interconnected by a ring component and are connected to each other through a carrier. The carrier also includes the output shaft. And since the sun gear is centered, the mesh is standard.

As an added benefit, planetary gearboxes have sliding surfaces, which reduce noise and vibration. Despite the high-quality of planetary gearboxes, it is important to properly lubricate them to avoid wear and tear. CZPT uses CZPT. In order to make the planetary gearboxes last a long time, the lubricant is usually incorporated in the planetary gearbox.

editor by Cx 2023-07-11

China factory Inline Straight Planetary Gear Speed Reducer, Gearmotor, Gearboxes Coupled with ABB Motor bicycle planetary gearbox

Product Description

Planetary Series High Power Gear Box

Housing is made of cast iron,which improve its rigidity and anti-vibration.

Sun and plant gears are processed by cementite and hardening,gears are processes by grinding,which improve the efficiency and lifetime of the gearbox.

Input mode:coaxial input,helical gear input,bevel-helical gear input.

Output mode:internal involute spline,hollow shaft with shrink disk,external involute spline,solid shaft with flat key.

Mounting mode:Horizonal vertical,torque-arm.

P series sizes 9~34 transmission stage:2~3 ratio:25~4000

Ratio will be larger in combination with H,R,K series.

RFQ

Q:Are you trading company or manufacturer?

A: We are manufacturer with over 20 years’ experience.

Q: How long is your delivery time?

A: Generally it is within 10 days if the goods are in stock, for goods produced as per order, it is within 35 days after confirmation of order.

Q: How long should I wait for the feedback after I send the enquiry?

A: Normally within 12 hours.

Q: What information should I give you to confirm the product?

A: Model/Size, Transmission Ratio, Speed, Shaft directions & Order quantity etc.

Q: Hong long is your product warranty?

A: We offer 12 months warranty from departure date of the goods.

Q: What is your payment terms? T/T 100% in advance for amount less than USD10000.-, 30% T/T in advance , balance before shipment for amount above USD10000.

If you have any other questions, please feel free to contact us below:

HOW TO CONTACT US?

Send your Inquiry Details in the Below, click “Send” Now!

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | P |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

| Customization: |

Available

| Customized Request |

|---|

Planetary Gearbox Advantages and Disadvantages

A planetary gearbox is a type of mechanical drive with a single output shaft. They are suitable for both clockwise and counterclockwise rotations, have less inertia, and operate at higher speeds. Here are some advantages and disadvantages of this type of gearbox. Let us see what these advantages are and why you should use them in your applications. Listed below are some of the benefits of planetary gearboxes.

Suitable for counterclockwise and clockwise rotation

If you want to teach children about the clock hands, you can buy some resources for counterclockwise and asymmetrical rotation. These resources include worksheets for identifying degrees of rotation, writing rules for rotation, and visual processing. You can also use these resources to teach angles. For example, the translation of shapes activity pack helps children learn about the rotation of geometric shapes. Similarly, the visual perception activity sheet helps children understand how to process information visually.

Various studies have been done to understand the anatomical substrate of rotations. In a recent study, CZPT et al. compared the position of the transitional zone electrocardiographically and anatomically. The authors found that the transitional zone was normal in nine of 33 subjects, indicating that rotation is not a sign of disease. Similarly, a counterclockwise rotation may be caused by a genetic or environmental factor.

The core tip data should be designed to work in both clockwise and counterclockwise rotation. Counterclockwise rotation requires a different starting point than a clockwise rotation. In North America, star-delta starting is used. In both cases, the figure is rotated about its point. Counterclockwise rotation, on the other hand, is done in the opposite direction. In addition, it is possible to create counterclockwise rotation using the same gimbal.

Despite its name, both clockwise and counterclockwise rotation requires a certain amount of force to rotate. When rotating clockwise, the object faces upwards. Counterclockwise rotation, on the other hand, starts from the top position and heads to the right. If rotating in the opposite direction, the object turns counterclockwise, and vice versa. The clockwise movement, in contrast, is the reverse of counterclockwise rotation.

Has less inertia

The primary difference between a planetary gearbox and a normal pinion-and-gear reducer is the ratio. A planetary gearbox will produce less inertia, which is an important advantage because it will reduce torque and energy requirements. The ratio of the planetary gearbox to its fixed axis counterpart is a factor of three. A planetary gearbox has smaller gears than a conventional planetary, so its inertia is proportional to the number of planets.

Planetary gears are less inertia than spur gears, and they share the load across multiple gear teeth. This means that they will have low backlash, and this is essential for applications with high start-stop cycles and frequent rotational direction changes. Another benefit is the high stiffness. A planetary gearbox will have less backlash than a spur gearbox, which means that it will be more reliable.

A planetary gearbox can use either spur or helical gears. The former provides higher torque ratings while the latter has less noise and stiffness. Both types of gears are useful in motorsports, aerospace, truck transmissions, and power generation units. They require more assembly time than a conventional parallel shaft gear, but the PD series is the more efficient alternative. PD series planetary gears are suitable for many applications, including servo and robotics.

In contrast, a planetary gear set can have varying input speed. This can affect the frequency response of the gearset. A mathematical model of the two-stage planetary gears has non-stationary effects and correlates with experimental findings. Fig. 6.3 shows an addendum. The dedendum’s minimum value is approximately 1.25m. When the dedendum is at its smallest, the dedendum has less inertia.

Offers greater reliability

The Planetary Gearbox is a better option for driving a vehicle than a standard spur gearbox. A planetary gearbox is less expensive, and they have better backlash, higher load capacity, and greater shock loads. Unlike spur gearboxes, however, mechanical noise is virtually nonexistent. This makes them more reliable in high-shock situations, as well as in a wide range of applications.

The Economy Series has the same power density and torque capacity of the Precision Helical Series, but it lacks the precision of the latter. In contrast, Economy Series planetary gearboxes feature straight spur planetary gearing, and they are used in applications requiring high torque. Both types of gearboxes are compatible with NEMA servo motors. If torque density is important, a planetary gearbox is the best choice.

The Dispersion of External Load: The SSI model has been extensively used to model the reliability of planetary gear systems. This model takes the contact force and fatigue strength of the system as generalized stress and strength. It also provides a theoretical framework to evaluate the reliability of planetary gear systems. It also has many other advantages that make it the preferred choice for high-stress applications. The Planetary Gearbox offers greater reliability and efficiency than traditional rack and pinion gear systems.

Planetary gearing has greater reliability and compact design. Its compact design allows for wider applications with concerns about space and weight. Additionally, the increased torque and reduction makes planetary gearboxes an excellent choice for a wide variety of applications. There are three major types of planetary gearboxes, each with its own advantages. This article describes a few of them. Once you understand their workings, you will be able to choose the best planetary gearbox for your needs.

Has higher operating speeds

When you look at planetary gearboxes, you might be confused about which one to choose. The primary issue is the application of the gearbox. You must also decide on secondary factors like noise level, corrosion resistance, construction, price, and availability worldwide. Some constructors work faster than others and deliver the gearboxes on the same day. However, the latter ones often deliver the planetary gearbox out of stock.

Compared to conventional gearboxes, a planetary gearbox can run at higher speeds when the input speed fluctuates. However, these gears are not very efficient in high-speed applications because of their increased noise levels. This makes planetary gears unsuitable for applications involving a great deal of noise. That is why most planetary gears are used in small-scale applications. There are some exceptions, but in general, a planetary gearbox is better suited for applications with higher operating speeds.

The basic planetary gearbox is a compact alternative to normal pinion-and-gear reducers. They can be used in a wide variety of applications where space and weight are concerns. Its efficiency is also higher, delivering 97% of the power input. It comes in three different types based on the performance. A planetary gearbox can also be classified as a worm gear, a spur gear, or a sprocket.

A planetary gearhead has a high-precision design and can generate substantial torque for their size. It also reduces backlash to two arc-min. Additionally, it is lubricated for life, which means no maintenance is needed. It can fit into a small machine envelope and has a small footprint. Moreover, the helical crowned gearing provides fast positioning. A sealed gearbox prevents abrasive dust from getting into the planetary gearhead.

Has drawbacks

The design of a planetary gearbox is compact and enables high torque and load capability in a small space. This gear arrangement also reduces the possibility of wear and tear. Planet gears are arranged in a planetary fashion, allowing gears to shift under load and a uniform distribution of torque. However, some disadvantages of planetary gears must be considered before investing in this gearbox.

While the planetary gearbox is a high precision motion-control device, its design and maintenance requirements are a concern. The bearing load is high, requiring frequent lubrication. Also, they are inaccessible. Despite these drawbacks, planetary gearboxes are suitable for a variety of tasks. They also have low backlash and high torsional stiffness, making them excellent choices for many applications.

As a result, the speed of a planetary gearbox varies with load and speed. At lower ratios, the sun gear becomes too large in relation to the planet gears. As the ratio increases, the sun gear will become too low, reducing torque. The planetary gears also reduce their torque in high-speed environments. Consequently, the ratio is a crucial consideration for planetary gearbox condition monitoring.

Excess drag may result from out-of-tolerance components or excessive lubrication. Drag should be measured both in directions and be within acceptable ranges. Grease and oil lubrication are two common planetary gearbox lubricants, but the choice is largely dependent on your application. While grease lubricates planetary gears well, oil needs maintenance and re-lubrication every few thousand hours.

editor by CX 2023-07-11

China 12v 24v 15w 30w 50w 100w 150w 3000rpm bldc motor 57mm dia braked brushless dc bldc motor with bake encoder or planetary gearbox with Great quality

Warranty: 1year

Model Number: bldc motor with brake

Usage: BOAT, Car, Electric Bicycle, FAN, Home Appliance, Cosmetic instrument, SMART HOME, Automation Industry, Automotive Industry

Type: Brushless Motor, bldc motor with brake

Torque: customized

Construction: Permanent Magnet

Commutation: Brushless

Protect Feature: Explosion-proof

Speed(RPM): customized

Continuous Current(A): customized

Efficiency: IE 1

Product Name: Brushless DC Motor

Keywords: 20w – 2000w bldc motor

Voltage: 12v 24v 36v 48v 310v or customized

Sensor: brushless motor with hallsensor

Ingress Protection: IP65

power: 1hp / 2hp / 3hp / 4hp / 5hp dc motor

keywords: brushless dc motor with gearbox encoder brake…

Certificate: CE, RoHS ISO

Packaging Details: with export carton . big quantity with pallet

Port: ZheJiang

Product Name: Brushless DC MotorNumber of Phase: 3 PhaseNumber of Poles: 4 Poles /8 Poles /10 PolesRated Voltage: 24v /36v /48v /310vRated Speed: 3000rpm /4000rpm /or customizedRated Torque: CustomizedRated Current: CustomizedRated Power: 23w~2500W

| Product Series | Poles No. | Rated Voltage | Rated Speed | Rated Torque | Rated Power | Motor Length | ||||||

| 42mm BLDC Motor | 8 | 24v | 4000rpm | 0.0625~0.25N.m | 26~105w | 41~100mm | ||||||

| 57mm BLDC Motor | 4 | 36v | 4000rpm | 0.055~0.44N.m | 23~184w | 37~107mm | ||||||

| 60mm BLDC Motor | 8 | 48v | 3000rpm | 0.3~1.2N.m | 94~377w | 78~120mm | ||||||

| 80mm BLDC Motor | 4 | 48v | 3000rpm | 0.35~1.4N.m | 110~440w | 78~138mm | ||||||

| 86mm BLDC Motor | 8 | 48v | 3000rpm | 0.35~2.1N.m | 110~660w | 71~138.5mm | ||||||

| 110mm BLDC Motor | 8 | 310v | 3000rpm | 1.65~6.6N.m | 518~2073w | 83~173mm | ||||||

| 130mm BLDC Motor | 10 | 310v | 3000rpm | 2.39~11.94N.m | 750~2500w | 115~190mm | ||||||

| Above only for representative products, products of special request can be made according to the customer request. | ||||||||||||

What is a Planetary Gearbox?

A planetary gearbox is a mechanical device in which the teeth of a planet mesh with the teeth of its sun or ring. The number of teeth and the spacing of planets will determine whether the teeth mesh correctly. In this article, we will learn more about planetary gearboxes. Besides understanding their working, you can also learn how to design your own. Here are some examples:

planetary gearboxes

If your car has an automatic transmission, then a planetary gearbox is the type you have. It is possible to find out if you have this type of gearbox by consulting the owner’s manual, calling the service department of your car’s manufacturer, or conducting a search using your favorite search engine. However, planetary gears are more complex and have many more components than standard gearboxes. The following information will explain more about this type of gearbox.

Planetary gearboxes use three different gear types to transmit torque. The sun gear sits in the center of the gear assembly, while the other gears rotate around it. A carrier connects the two gears, and is designed to set the spacing between them. When the gears are rotated, the carrier will spin, enabling the entire assembly to work together. The carrier also incorporates the output shaft. For this gearbox to work effectively, it must meet the application’s requirements.

There are three main types of planetary gearboxes: the basic model is highly efficient and transmits 97% of the power input. The earliest models are not complex, but they do have some key differences. Some of these differences make them ideal for various applications. For example, a planetary gearbox can operate in alternating and continuous operation, with the output support having internal grooving. Some designs have more than one output shaft, allowing the user to choose the configuration and torque that is best for their application.

One of the main differences between a planetary gearbox and a conventional one is the way the planetary parts move. A planetary gearbox may have multiple axes for increased torque. A planetary gearbox can provide a torque up to 113,000 N.m. by rotating its maximum teeth simultaneously. They are the ideal choice for space-constrained applications. For instance, a car with small spaces can install one with ease.

A planetary gearbox’s gear ratio is determined by the ratio of the sun gear to the ring gear. The number of teeth on the sun gear is a way to adjust the gear ratio. Smaller sun gears result in larger planetary gear ratios, while larger ones cause a decrease in torque. The ratio between planetary gears ranges from 3:1 to 10:1, with the lowest ratio being three. The greatest possible ratio is 10:1.

A planetary gearbox has many benefits. The compact design makes them a more efficient choice for small motors and is advantageous for servo functions. Planetary gearboxes have low inertia, which is an important factor, especially in servo applications, since the inertia of the gearbox adds to the motor’s load inertia. The planetary gearboxes are typically lubricated with grease or oil, so you don’t need to worry about re-lubrication or maintenance.

planetary gearboxes with output shaft

The advantages of planetary gearboxes are numerous. They are widely used in many applications, from automobiles to medical equipment, goods & personnel lifts to machine tools. They are also used in derrick & dockyard cranes and slewing drives. These gearboxes are available in various sizes and shapes, ranging from small to extremely large. There are many different types, and each is designed to suit its intended use.

The LP generation 3 gearhead series combines maximum quality with economic precision in a low-backlash planetary gearbox. The output shaft version is especially suited for high-speed, highly dynamic cyclic operation. Another version is the SP+ HIGH SPEED. The SP+ high-speed version is designed to achieve maximum speeds while in continuous operation. If you need a planetary gearbox with an output shaft, look no further. It is the best choice for many applications.

As the name suggests, a planetary gearbox incorporates planetary parts and an output shaft. The outer gears (also called the planetary gears) are connected by a carrier to the output shaft. The carrier is then connected to the output shaft by a ring. There are two or more planetary gears inside the planetary gearbox. Each gear is connected to a carrier, which is connected to the output shaft.

An epicyclic planetary gear train can be assembled so that the planet gear rolls around the sun gear. In the wheel drive planetary gearbox, the planetary gears are grouped over the housing to optimize the size and weight of the system. The planetary gear train can handle torques as high as 332,000 N.m., with the ring gear being fixed while the sun gear is movable.

Another advantage of a planetary gearbox is that it uses many teeth at once. This allows for high speed reduction and high torque transmission, and it is extremely compact. Planetary gearboxes with output shaft are ideal for space-constrained applications. Their compact size and minimal weight make them a popular choice in many industries. They are also known as epicyclic gears and are used in many different types of machines.

A planetary gearbox can have three components. A central sun gear, an outer ring known as the inner gear, and an output shaft. These three components are linked by a carrier. The carrier rotates so that the input and output gears are in sync. They also have a standard gap between the gears. The carrier also acts as the output shaft. They can be used to create small machines, such as a bicycle acceleration hub.

planetary gearboxes with integer number of teeth

When designing a planetary gearbox, one must determine the amount of tooth count. This figure is known as the mesh load factor Kg, and is based on the normal tooth forces that are generated in each mesh. The number of planets, the error in the gear design, and the rigidity of the housing all affect Kg. Depending on the type of application, Kg can be calculated by using different standards.

In a typical planetary gearbox, the ratio is an integer number, and the lowest is 3:1. At a ratio of 10, the sun gear is too large and the sun wheel is too low to provide a sufficient amount of torque. In most cases, the ratio is an integer value, and the teeth are evenly spaced. The gear mesh is then balanced to grade 2. The carrier is measured three-dimensionally to detect the accuracy of the planet pin hole in the carrier.

In the simplest case, each planetary gear mesh produces a dynamic signal at its mesh frequency. These signals can cancel or reinforce in various ways. A helix angle, however, introduces axial forces into the gear mesh, which can be cancelled or reinforced in the same way as torques. As the helix angle is an integer number, this planetary gear model does not necessarily require infinite precision.